Clutch cover complete BGM PRO Superstrong CNC ULTRALUBE - Vespa Largeframe 1958-1962

More than just a cover: The BGM PRO Superstrong CNC ULTRALUBE cl utch cover for early Vespa Largeframe models (1958 to 1962) comes here as a completely pre-assembled kit - including clutch arm, clutch arm spring, release lever, separating mushroom, O-rings and mounting material. The silver CNC design enables conversion to the modern PX clutch type and at the same time creates space for reinforced and CNC-machined sports clutches.

Why this cover is particularly important for early largeframe engines

The first Vespa largeframe engine cases (VBA, VBB1, VNA2, VNB1-3, VGLA, VGLB) have a flatter design in terms of the distance between the sealing surface of the clutch cover and the crankshaft bearing. The originally installed, flat clutches are more difficult to obtain and are often already at their limit with moderate power increases. The BGM PRO CNC cover is deliberately designed higher for these engines and allows the use of standard PX/Cosa clutch types including modern CNC versions - without milling work on the housing. The standard thin washer (approx. 1.5 mm) is still used.

Complete and ready to fit

✔️ Completely pre-assembled - unpack, install, drive

✔️ CNC clutch arm with two cable pull positions: more disconnect travel or less manual force

✔️ Integrated ULTRALUBE oil guide reliably lubricates the disconnect mushroom and pressure bearing

✔️ Higher inner contour for oversize Sport and Race clutches

✔️ Specially for Vespa Largeframe 1958-1962 (conversion to PX clutch type)

ULTRALUBE - Lubrication where it counts

Many machined out series covers lose the oil supply for the separating mushroom during machining. The BGM PRO ULTRALUBE coverguides the transmission oil specifically to the release bearing and pressure plate. This reduces wear, improves the separation behavior and ensures high long-term stability - especially in combination with powerful clutch springs and high-torque engines.

Conversion to clutch type PX

Thanks to the higher design of the cover, a PX/Cosa clutch pack can be installed in the early Largeframe engines. This means that robust Superstrong and other CNC clutches are available which are much better suited to the increased performance level of modern setups than the flat original clutches. The inside of the cover is contoured in such a way that the standard oversize Sport and Race clutches can be fitted without additional reworking of the cover.

Compatibility

Largeframe 1958-1962 (BGM8293S - silver)Suitable for Vespa:

- VBA1T

- VNA2T

- VBB1T

- VNB1T to VNB3T

- VGLA1T

- VGLB1T

Note: This cover replaces the flat original version and creates space for PX/Cosa clutches and CNC systems. The thin original washer (approx. 1.5 mm) remains in use.

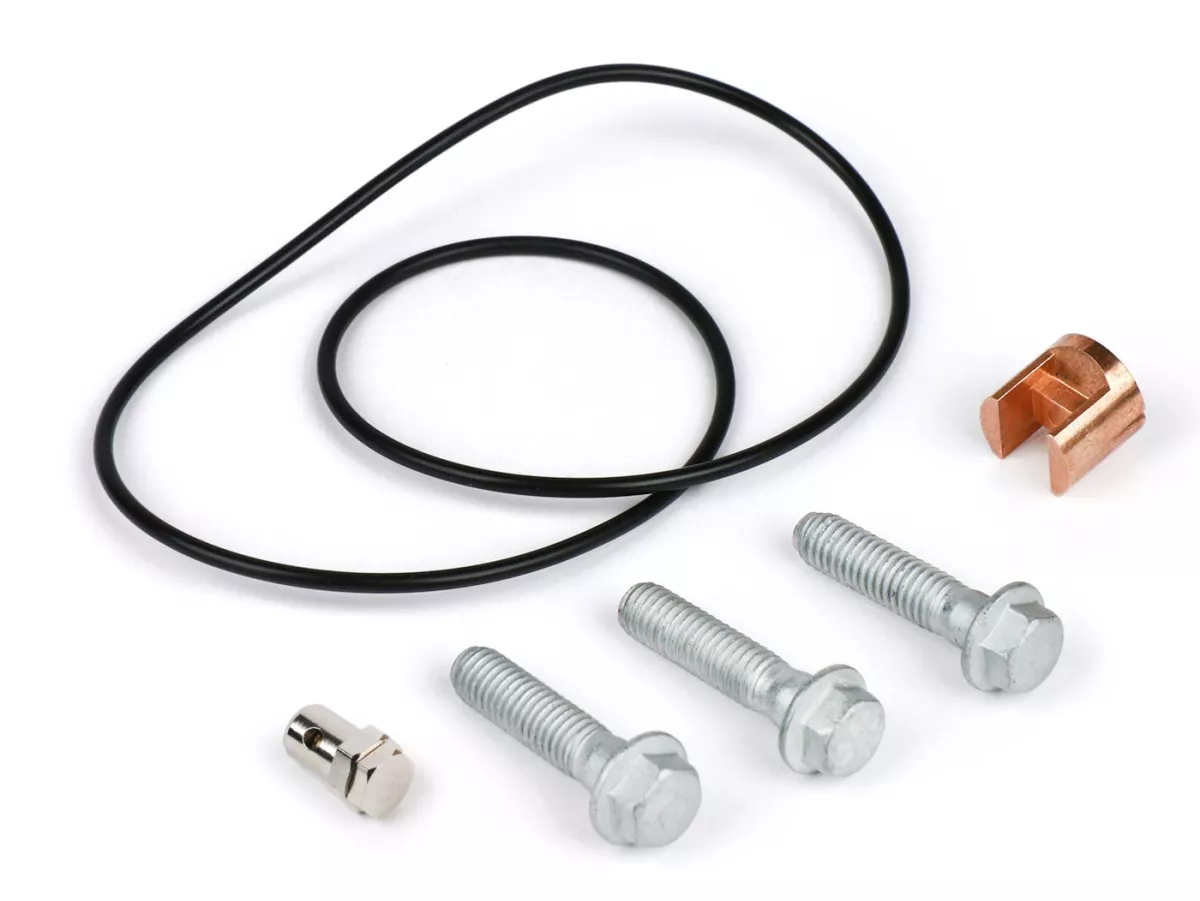

Scope of delivery

✔️ Clutch cover BGM PRO Superstrong CNC ULTRALUBE, silver

✔️ CNC clutch arm with two mounting positions

✔️ Clutch arm spring and release lever

✔️ Separating mushroom, O-rings, mounting material and screws

✔️ Already fully pre-assembled

✔️ Installation with the standard 1.5 mm washer

Note on venting: The venting screw for the clutch cover is not included. The existing screw from the old cover can continue to be used, alternatively a practical accessory bleeder is available.

FAQ - frequently asked questions about the BGM PRO clutch cover Superstrong CNC ULTRALUBE (1958-1962)

Does the cover fit large CNC clutches without reworking?

Yes. The inner radius and installation depth are designed so that modern PX/Cosa CNC clutches and oversize sports clutches can be used without machining the cover. No milling work is required on the housing side.

How do I set the lever ratio on the clutch arm?

The CNC arm has two cable holes. If the cable is hooked into the inner hole, more separation distance is available, but the manual force increases slightly. Actuation is easier in the outer hole, with slightly less separation travel. This allows the feel of the lever to be selected to suit the clutch setup.

Does the cover ensure the oil supply to the release bearing?

Yes. The integrated ULTRALUBE oil guide supplies the release mushroom and pressure bearing with oil in a targeted manner. This means that lubrication is maintained even with powerful springs and frequent clutching and the release system wears much more slowly than with unguided solutions.

What should I pay particular attention to with early large-frame engines?

The cover is designed for engine housings with a flat clutch support (VBA1T, VBB1T, VNA2T, VNB1-3, VGLA1T, VGLB1T). It replaces the flat original design and creates space for the PX clutch type. Important: The original thin washer (approx. 1.5 mm) is retained in the assembly.

Can I continue to use the old two-piece clutch arm?

No. The wide, two-piece arm of the early models is replaced by the one-piece CNC clutch arm supplied. This is already fitted and matched to the BGM PRO cover. It is no longer necessary to purchase the PX clutch arm separately with this complete kit.

Fitting instructions

The cover is screwed onto the engine housing using the enclosed mounting material. Lay the clutch cable tension-free and hook it into the inner or outer hole of the CNC arm as required. Then adjust the clutch play and check the disconnection behavior. Ensure clean sealing surfaces and correct oil filling during all work.

DE | €

DE | €