Postage free from 99€ (DE)

High customer satisfaction

Shipping today with order in 2 h 7 min

-

all

Tip of the day

-

Vespa Classic

-

Vespa Modern

-

Moped classic

-

Lambretta

-

Scooter 50-850cc

- Vespa Classic

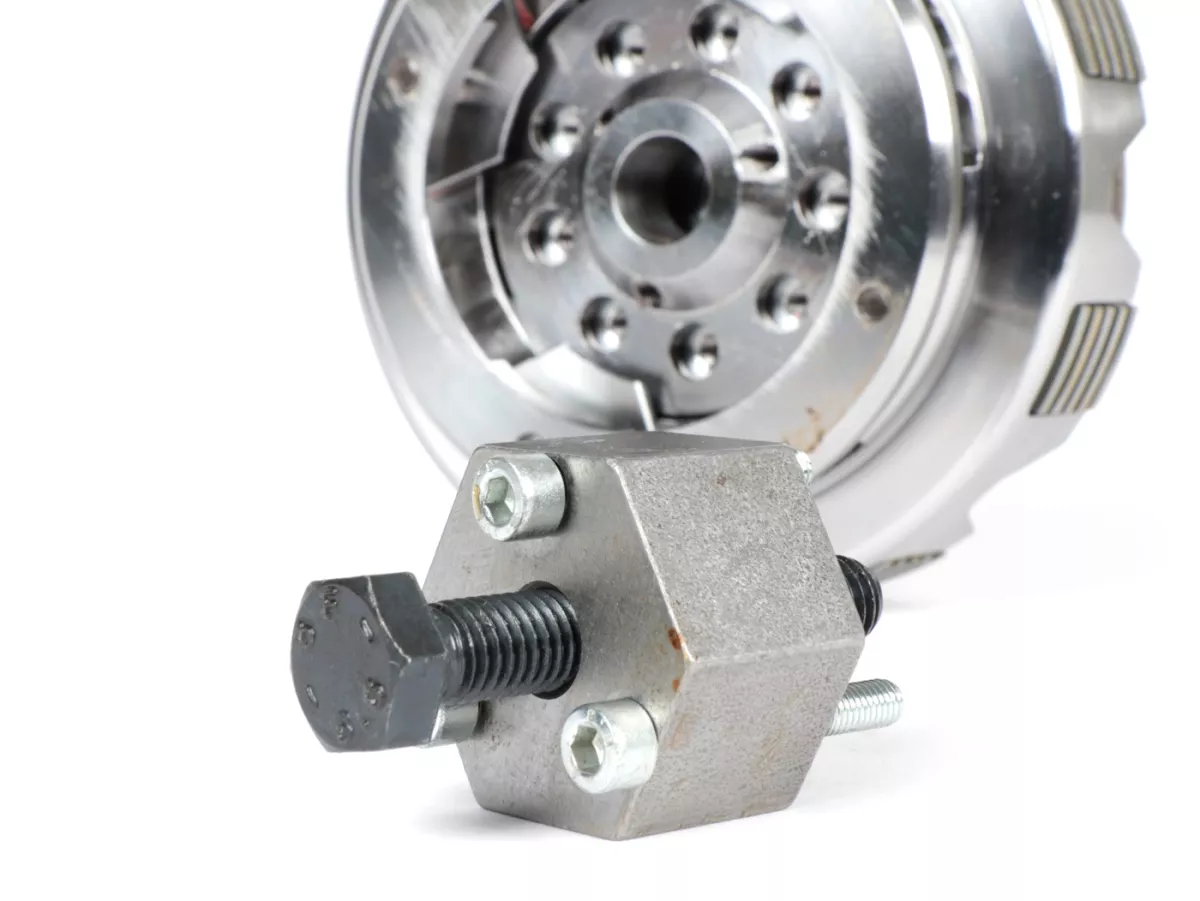

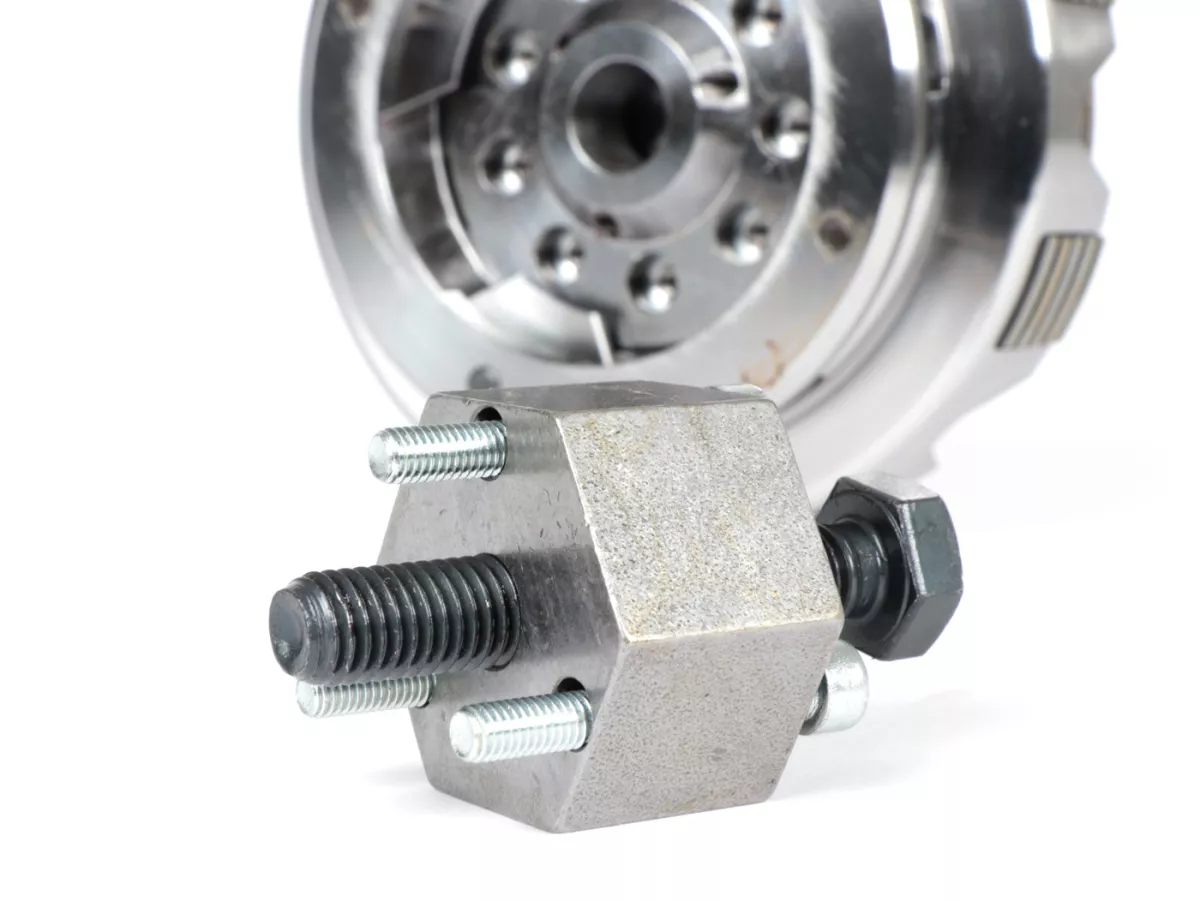

- Clutch -KINGWELLE 5S-R DragBikeClutch (for long auxiliary shaft DRT, Faio etc.)- Vespa V50, V90, SS50, SS90, PV125, ET3, PK50, PK80, PK50 S, PK80 S, PK125 S, PK50 XL, PK125 XL, ETS, PK50 HP, PK50 SS

DE | €

DE | €