Postage free from 99€ (DE)

High customer satisfaction

Shipping today with order in 5 h 45 min

-

all

Tip of the day

-

Vespa Classic

-

Vespa Modern

-

Moped classic

-

Lambretta

-

Scooter 50-850cc

- Vespa Classic

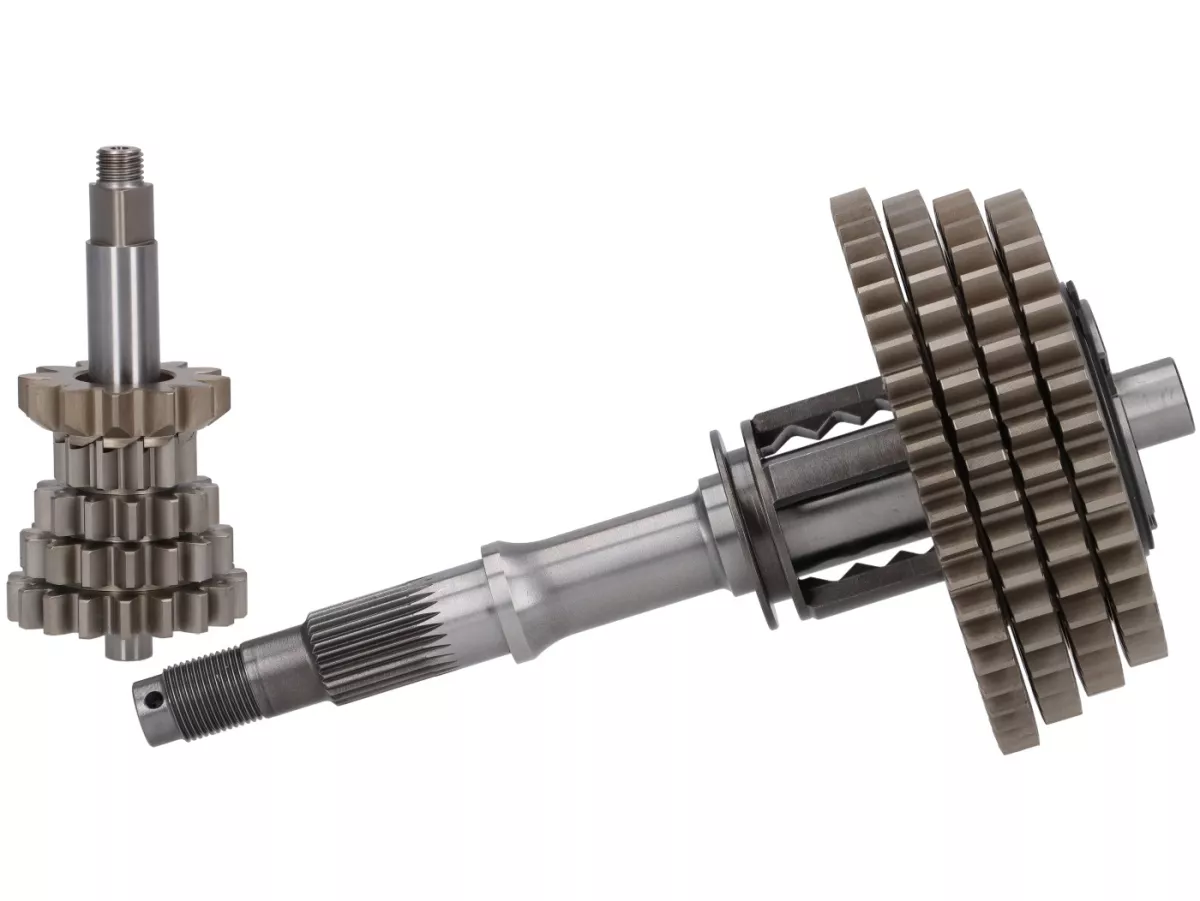

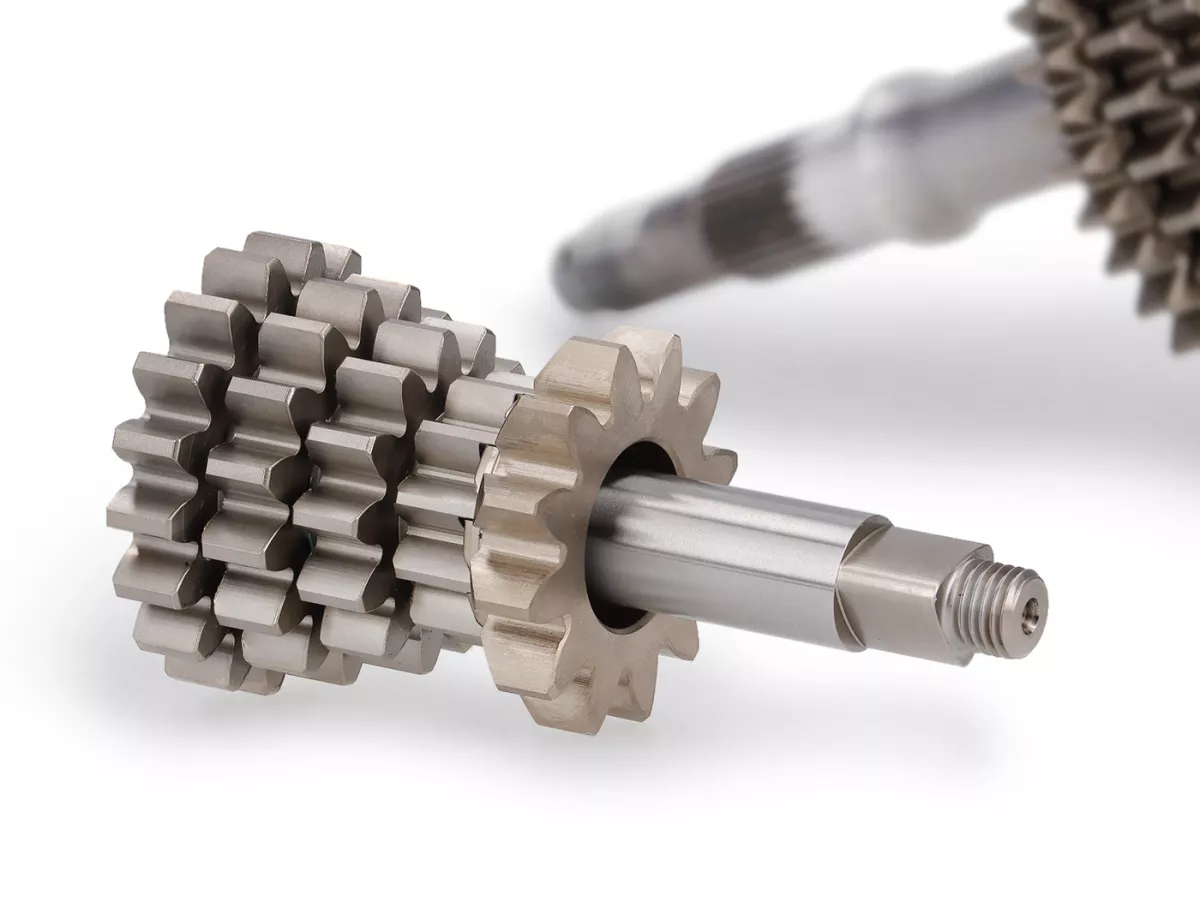

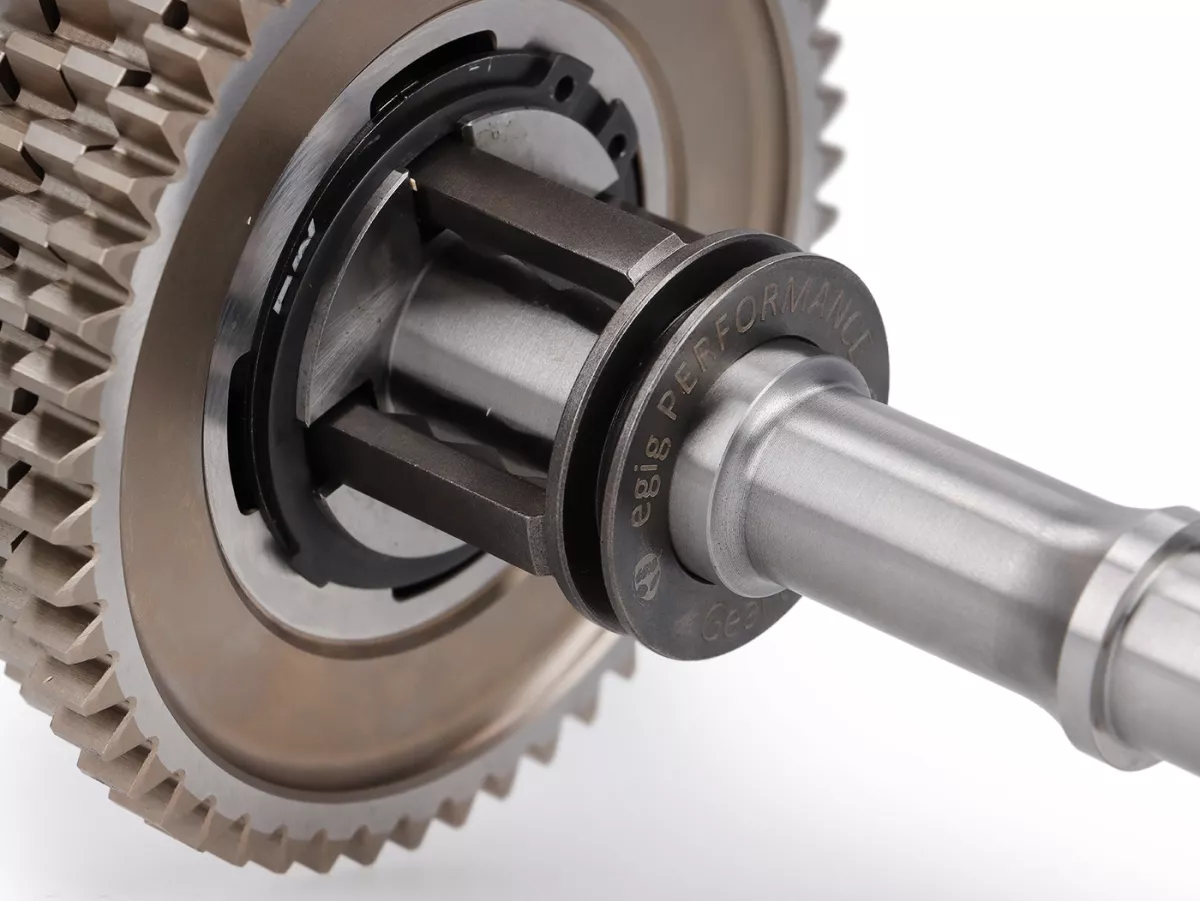

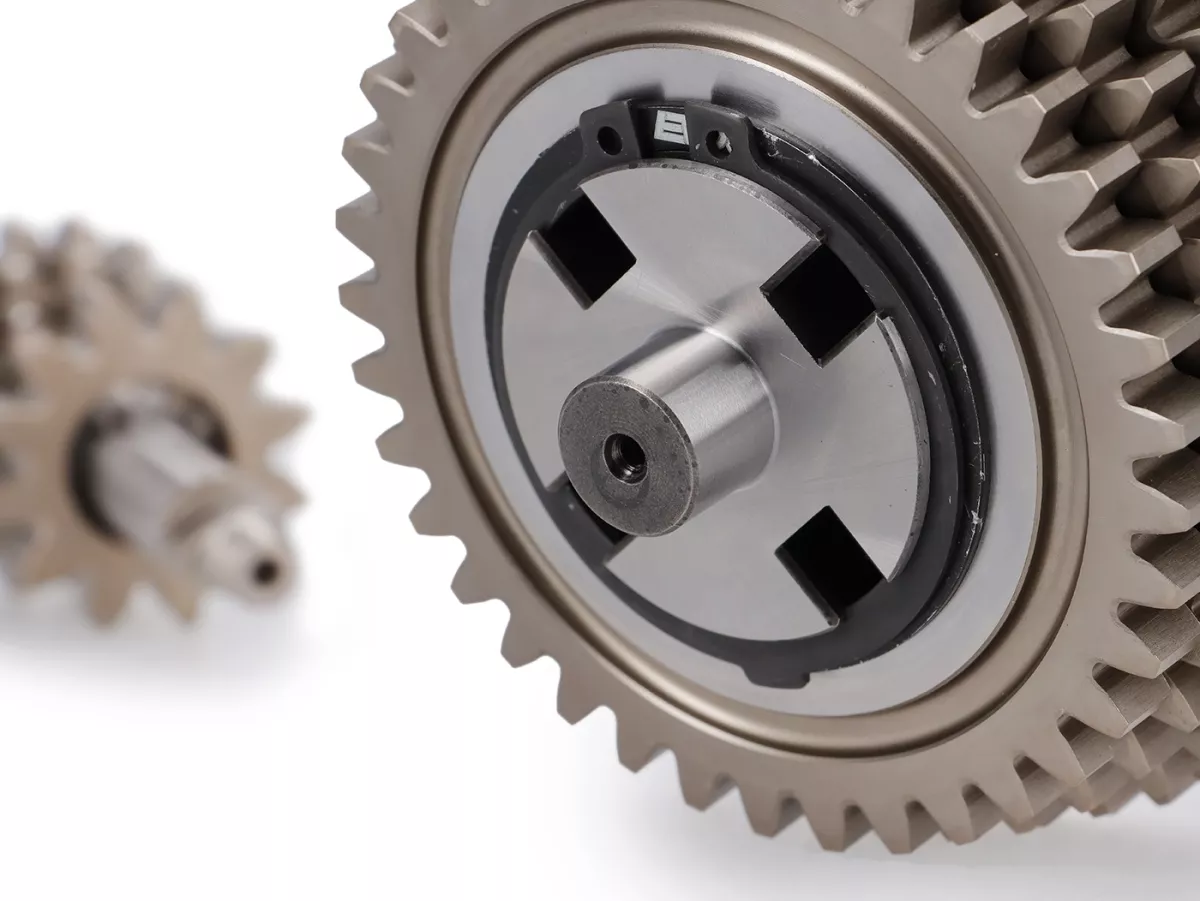

- Complete gearbox (gears incl. main shaft + auxiliary shaft) for Piaggio case -EGIG/FAIO X-TRA STRONG, CNC drive shaft - Vespa Smallframe V50, PV, ET3, PK, HP 4-speed- 18/37-15/38-12/42-11/52 - auxiliary shaft with poligon

DE | €

DE | €