Postage free from 99€ (DE)

High customer satisfaction

Shipping today with order in 6 h 33 min

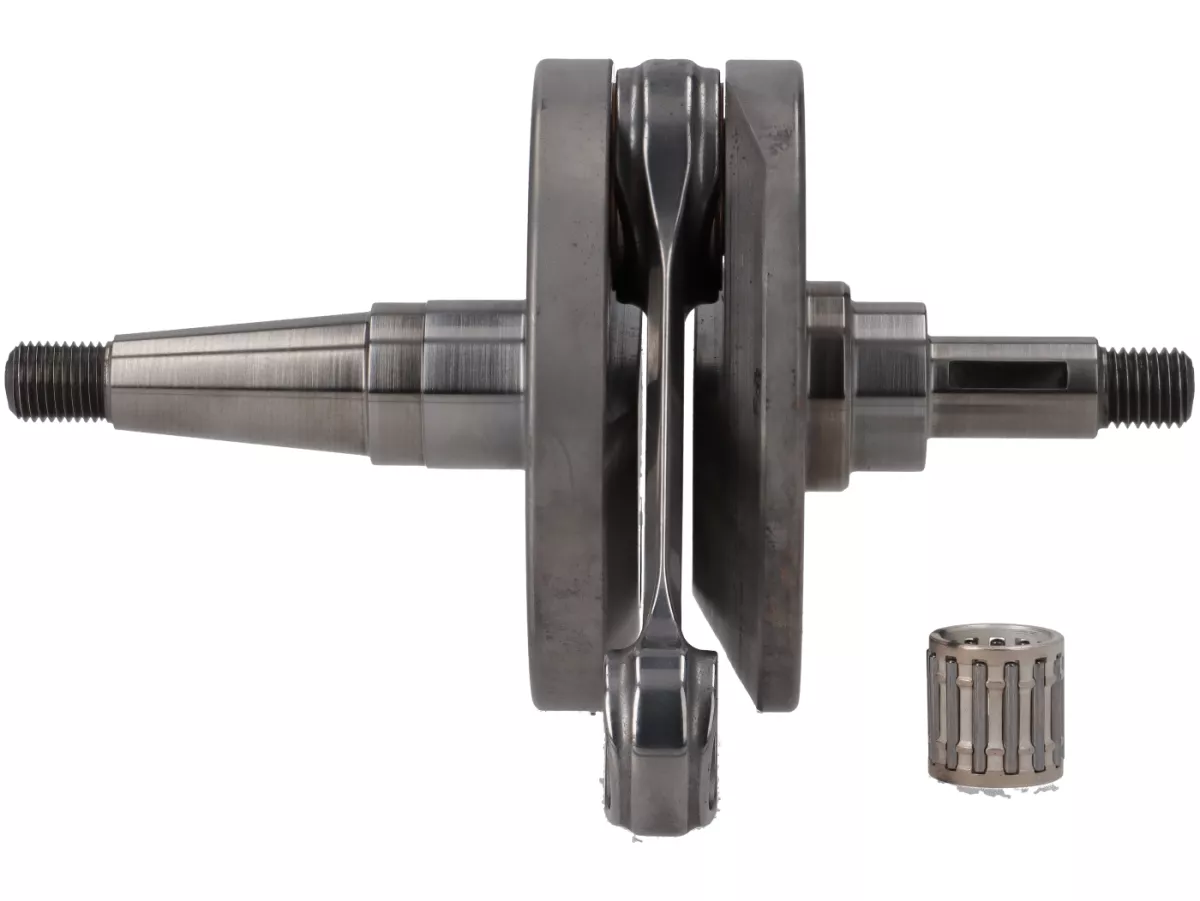

- Crankshaft - DEXTER RACING - Largeframe full cheek, 60 mm stroke, 105 mm connecting rod - Vespa PX125, PX150, Cosa 125/150, Sprint Veloce, GTR 125, TS 125, Super 150

DE | €

DE | €