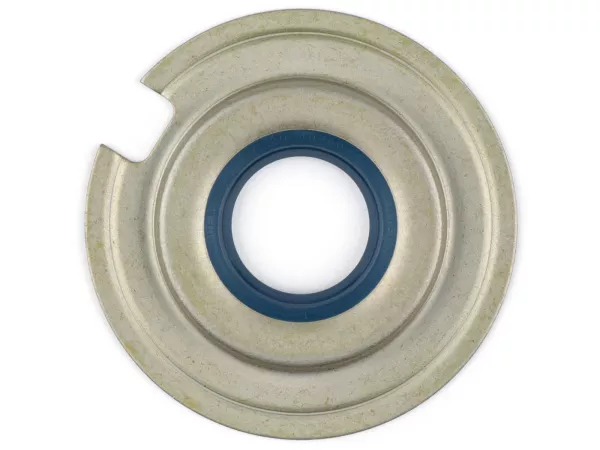

Mazzucchelli K2D rotary slider crankshaft 60 mm for Vespa PX125/PX150

Sport crankshaft from Mazuchelli with 60 mm stroke (+3 mm compared to standard).

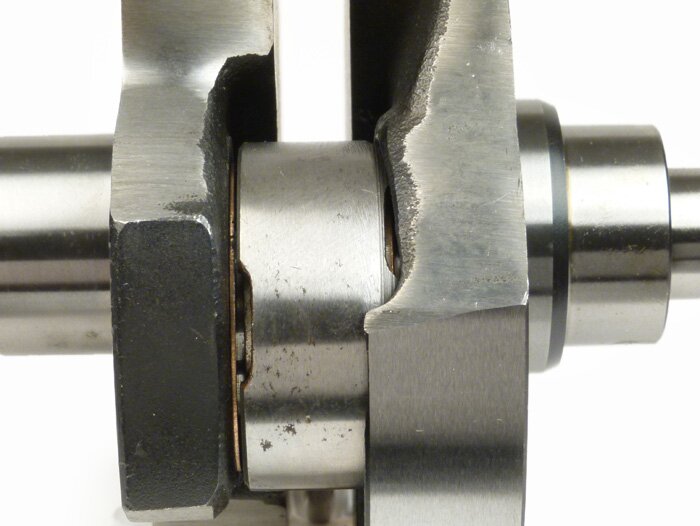

Mazuchelli now also manufactures its K2D rotary slider crankshafts from the same material that has been used for years for the full cheek shafts. Mazuchelli advertises with the old material designation K2D, which would correspond to the alloy 18CrNiMo5 according to today's standardization. Material analyses have not been able to confirm this, but the alloy used is still significantly tougher and harder than the 36CrMn5 usually used by Mazuchelli. Due to the higher core strength, a higher pressing dimension can be realized on the crankpin, an important criterion for the torsion resistance of crankshafts. Twisting of the crank webs is one of the biggest problems in tuned PX engines due to a design flaw by Piaggio (the crank webs are too narrow). An increase in torsional rigidity through better base material is therefore essential, but unfortunately it remains a weak point in the overall PX engine concept.

It is an ideal addition to all sports and racing cylinders. The intake timing angle of this crankshaft is relatively long, making it more difficult to tune with the SI24/SI26 carburetors than with a Stoffi or BGM crankshaft. The long intake timing after top dead center ensures that a lot of the mixture already drawn in is forced back through the carburetor in the lowest speed range (so-called blow back). As a result, the mixture is heavily greased and the engine runs unevenly and stutters.

The ideal companion for this shaft is therefore a larger carburettor, which is inevitably accompanied by a longer intake path for this type of engine. This already dampens the spitting back into the carburettor relatively strongly, and an additional mounted resonance chamber (so-called boost bottle) makes it even easier to tune the engine.

The larger carburettor cross-section fits well with the long control angles of the shaft and enables a strong increase in performance in the upper speed range compared to early closing crankshafts. Unfortunately, this is also accompanied by a loss of engine elasticity. Unfortunately, the Mazuchelli shaft does not achieve the same width at the rotary valve timing cheek and at the shaft seal seat as the BGM shafts. As a result, the timing slot in the engine housing cannot be widened as much as with a BGM crankshaft

.

The additional stroke must be compensated for in cylinders designed for the standard stroke of 57 mm. To do this, use either a 1.5 mm head OR a 1.5 mm base gasket. It is not necessary to work with a 3 mm gasket. The additional stroke of 3 mm is distributed over 1.5 mm towards bottom dead center and 1.5 mm towards top dead center.

A base gasket increases the control angle of the cylinder and thus creates the conditions for a sporty and speed-oriented power delivery. For full power, however, the exhaust angle often has to be increased in order to compensate for the disproportionately increased overflow angle compared to the exhaust angle. For everyday engines, it is usually advisable to compensate for the stroke with a 1.5 mm head gasket.

Cylinders designed for 60 mm stroke (Polini 221, Pinasco 225) do not require an additional compensating gasket.

- Stroke: 60 mm

- Connecting rod length: 105 mm

- Engines: PX80, PX125, PX150, Cosa125, Sprint Veloce 150

- Stroke journal: 20 mm (solid material)

- Required stroke compensation: 1.5 mm (foot or head for cylinders with 57 mm stroke)

Conclusion: High-quality material with a long intake control angle for very good torque and increased performance in the upper rev range.

(US)

DE | €

DE | €