Engine case -POLINI- Vespa PX125/150 and PX200 - reed controlled intake ex works

The completely redesigned POLINI engine cases for Vespa PX125/150 and PX200 combine modern flow technology with the robustness of classic largeframe engines. The concept is based on a vane-controlled intake, while retaining compatibility with original Vespa components and creating an extremely stable basis for high-performance street and racing setups.

For PX125/150 and PX200

reed valve intake 28/30 mm

CFD optimized flow

FEM reinforced structure

Intake concept and carburetor mount

Instead of the classic rotary valve intake, POLINI uses a completely redesigned reed valve intake for these engine cases. The flat reed valve channel replaces the rotary valve-dependent control and thus eliminates all problems that can arise from a worn or damaged intake sealing surface.

Changeover from the standard rotary valve to a modern reed system with flat lamella.

Significantly more stable mixture formation and cleaner response over the entire rev range.

Designed for racing reed valve blocks with 28/30 millimeter carburetors - ideal for performance-oriented setups.

Alternatively available: Racing reed valve block in pyramid shape without separate lubrication, with its own intake manifold for 28/30 millimeters.

Despite the new intake concept, the housings remain fully compatible with original Vespa parts in their periphery. This simplifies assembly enormously and allows existing components to continue to be used if they match the desired performance level.

Mechanical and structural optimizations

POLINI has not simply copied the engine housing, but has rethought many of the details. The two halves are numbered as a pair at the factory and machined together. This means that the bearings and sealing surfaces are precisely aligned with each other, which significantly improves running smoothness and durability.

Housing halves are manufactured and numbered as a pair for a perfect bearing fit and plane-parallel contact surfaces.

The crankcase and transfer ports are designed for optimum gas flow using CFD simulation.

The swing arm has been redesigned and reinforced using FEM analyses, while additional ribs and material reserves allow the use of wider rear wheels.

The area around the rear axle stub is reinforced in the transmission housing to cope with the higher torque of more powerful engines.

Bearings, seals and screw connections

The developers have also addressed many of the classic weak points of the PX engines in detail. For example, the design on the clutch side has been modified so that the radial sealing ring pack can no longer move out of its seat unnoticed. A precisely machined steel flange provides additional support for the crankshaft bearing.

Modified design on the clutch side to reliably prevent the radial shaft seal from migrating out.

Ground steel flanges as a support for the crankshaft bearing on the clutch side, for maximum dimensional stability.

Larger crankshaft bearing on the ignition side (25 x 52 x 15 millimeters) for smoother running and longer service life.

Instead of the classic M7 through bolts, M8 hexagon bolts are used, which increases the rigidity of the entire housing assembly.

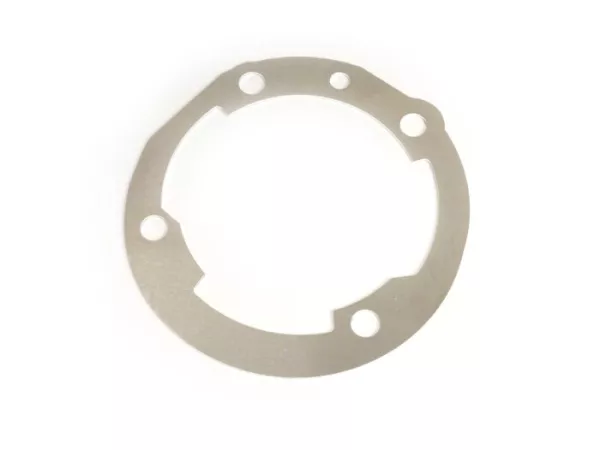

The central housing seal is no longer required; instead, the two halves of the housing lie directly on top of each other with an enlarged contact surface. In conjunction with a suitable sealant, this results in a very stable and largely temperature-resistant connection.

Chassis connection and peripherals

In addition to pure engine performance, POLINI also keeps an eye on the peripherals. The attachment points of the shock absorber and cylinder base are specifically reinforced in order to provide a stable basis even with tougher suspension set-ups and higher continuous performance.

Reinforced shock absorber connection, suitable for sporty suspension set-ups.

Reinforced cylinder contact surface for high clamping forces and stable sealing conditions with racing cylinders.

Preparation for electric starter - the housing is designed for the installation of an electric starter.

The transmission oil filler neck has been repositioned to increase the oil quantity and thus the lubrication reserve.

Material and manufacturing quality

The motor housings are cast from a high-quality aluminum alloy Al Si10 Mg T6 using the permanent mold process. Heat treatment is then carried out to optimize the mechanical properties.

Light metal alloy Al Si10 Mg T6 for high strength with moderate weight.

Heat treatment for stable material properties even at high continuous temperatures.

Enlarged sealing surfaces and reinforced areas at all critical points.

Field of application

POLINI engine cases for Vespa PX125/150 and PX200 are designed as a platform for demanding road and racing engines. Whether powerful touring engine or uncompromising racing setup - the combination of modern reed valve intake, optimized flow and reinforced structure offers ample reserves for setups far beyond the standard performance without losing the basic Vespa DNA.

FAQ: POLINI Vespa PX engine case

Frequently asked questions

How does the POLINI case differ from the original PX engine case?

In addition to the change to reed valve intake, the flow, bearings and structure have been completely revised. The cases are more stable, offer space for wider tires, larger bearings and an optimized oil supply, but remain compatible with most original Vespa components in the periphery.

Do I necessarily have to use a 28/30 millimeter carburetor?

The housing is designed for racing reed valve systems of this size, as this is where the potential is best utilized. Smaller carburetors are technically possible, but do not fully exploit the advantages of the system.

What about separate lubrication?

Variants with separate lubrication are available for the flat reed intake. There is also a pyramid reed block without an oil pump with its own intake manifold. Depending on the set-up, this can be used for mixed or separate lubrication.

What is the advantage of the larger crankshaft bearing on the ignition side?

The larger bearing improves running smoothness and increases the service life at high engine speeds and with powerful cylinders. Especially in combination with heavy fan wheels or high engine speeds, this is a plus for operational reliability.

For whom is it worth switching to POLINI motor housings?

It is particularly useful for new builds and engines whose performance target is significantly higher than the series. If you are working with a large cylinder, reed valve intake and modern exhaust system, you get a housing base that does not make the rest of the setup a limiting factor.

DE | €

DE | €