Postage free from 99€ (DE)

High customer satisfaction

Shipping today with order in 10 h 44 min

-

all

Tip of the day

-

Vespa Classic

-

Vespa Modern

-

Moped classic

-

Lambretta

-

Scooter 50-850cc

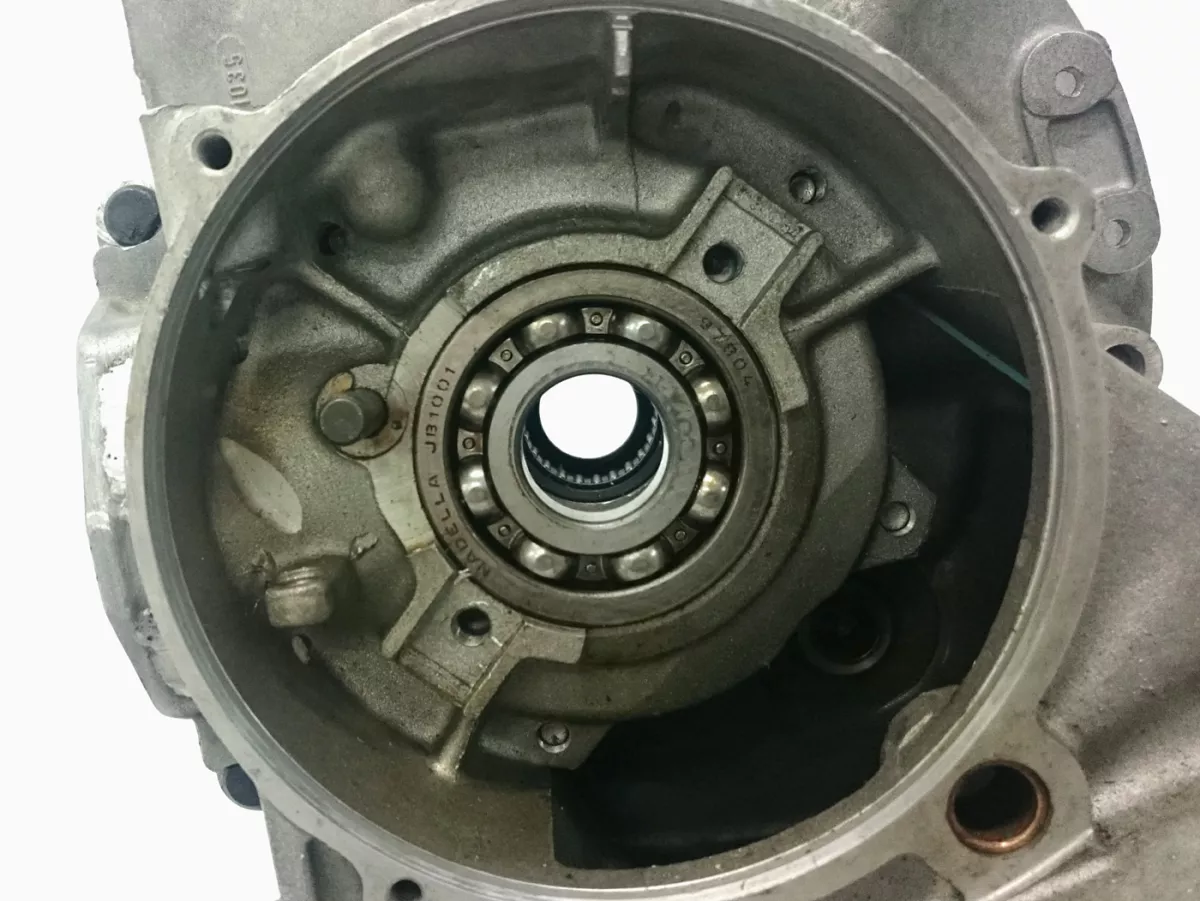

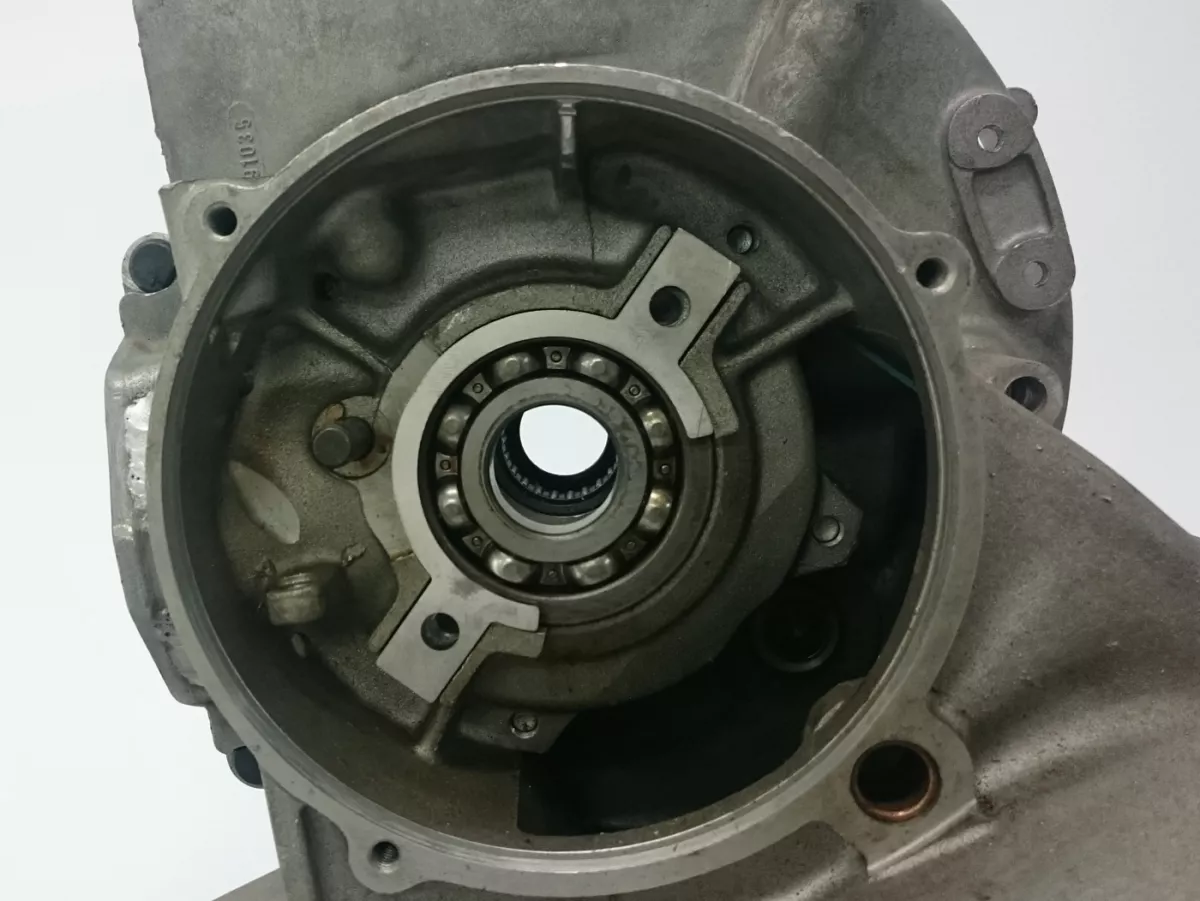

- Locking ring drive side bearing -TD-Customs- Vespa P -bolt on type

DE | €

DE | €