With the BGM ORIGINAL Race engine swingarm mount service kit, you get all the relevant parts to completely renew and simultaneously improve the lateral guidance of the engine on Piaggio/Gilera 125-180 cm³ 2-stroke engines. The tight BGM Race Silentblock reduces engine vibration without transferring additional vibrations to the frame - on the contrary: compared to many tuning mounts (e.g. PM or BPB), the engine is guided more quietly and runs noticeably more smoothly.

The engine swing arm mount (a parallelogram) is a safety-relevant component and is specifically checked during the main inspection. Faulty bearings cause spongy handling, misalignment in the rear axle and poor directional stability. This kit replaces all the important components around the silent block and restores the bearings to a defined, tight condition - perfect for MOT, everyday use and sporty driving.

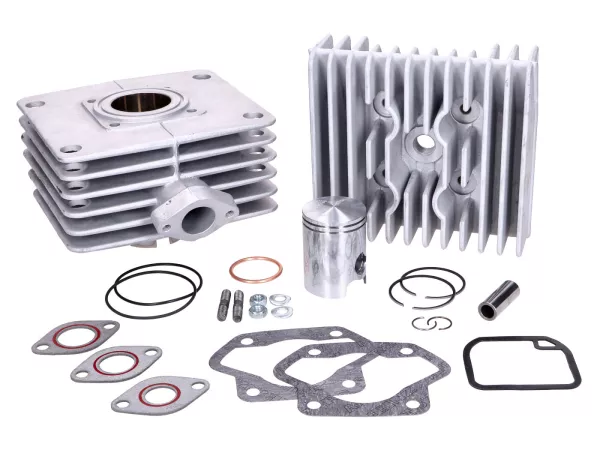

Scope of delivery - what is included in the kit

1× BGM ORIGINAL Race engine swing arm bearing (tight silent block version for the engine housing)

4× original Piaggio plastic engine swingarm bush for clean guidance of the swingarm axle

4× BGM PRO O-ring 21 x 3 mm made of EPDM to seal the engine swingarm against dirt and splash water

Note: The BGM ORIGINAL Race Silentblock is designed to be firmer than the standard part and therefore significantly improves engine guidance. At the same time, comfort remains suitable for everyday use, as the rubber compound has deliberately not been chosen to be too hard.

Function and advantages of the BGM Race mount

The standard mounts tend to wear out as the vehicle ages and the engine's performance increases. This leads to imprecise handling and can result in complaints at the vehicle inspection. The BGM ORIGINAL Race insert uses a firmer rubber compound and optimized geometry to better absorb lateral forces. This keeps the engine precisely aligned and the power is transferred cleanly to the rear wheel.

Significantly more stable lateral control of the engine - noticeably more precise handling at higher speeds.

Less rocking during load changes and in fast bends, ideal for sporty riding and long tours.

Reduced vibrations compared to some hard solid material tuning mounts, particularly pleasant under partial load.

Thanks to EPDM O-rings, the bearing remains sealed for longer, even when frequently exposed to rain or winter salt.

Installation tip: Remove and insert silentblocs

The cleanest way to change the engine swing arm bearing is with a simple "threaded rod press". This prevents damage to the frame or engine housing:

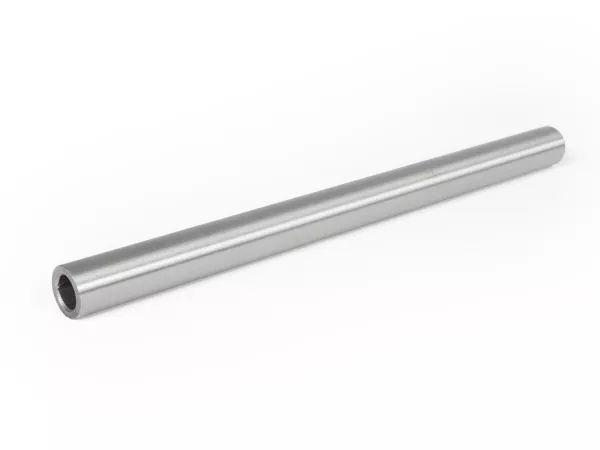

1. have a sufficiently long threaded rod (e.g. M10), two nuts, several washers and a suitable nut from the ratchet box ready.

2. to press out the old silent block, position the nut on the outlet side so that the rubber and metal sleeve can be pressed into the nut. Use washers as a support on the opposite side.

3. insert the threaded rod through the bearing bore, tighten the nuts and pull the old silent block into the nut in a controlled manner. If necessary, use a little rust remover or heat (hot air gun).

4 Before inserting the new BGM Race silent block, clean the bore and lightly coat with assembly paste or acid-free grease.

5. pull in the new silent block with the threaded rod construction in the opposite direction, making sure that the contact surfaces are aligned and the rubber is not tilted.

6. finally, insert the new EPDM O-rings and plastic bushes, fit the axle and tighten all screw connections to the torque specified by the manufacturer.

Tip: A slightly warmed motor housing and a previously cooled silent block in the freezer compartment will also make it easier to tighten.

TÜV aspect and area of application

The rear engine swingarm mount determines to a large extent how precisely the engine is guided in the frame - and therefore how cleanly the rear wheel follows the vehicle's centerline. Inspection bodies pay particular attention to play and misalignment at this point on older maxi scooters with Piaggio 2-stroke engines. With the BGM ORIGINAL Race service kit, the bearing is technically on a par with a new vehicle, generally even more precise than ex works.

Ideal for restorations, engine revisions and performance kits (e.g. 172cc cylinders) on a Piaggio/Gilera 2T basis.

Ensures a defined, test-safe clearance on the swingarm bearing - an important point for HU/TÜV.

Always recommended if the engine has been removed anyway or if the vehicle shows conspicuous self-steering behavior.

FAQ: Engine swing arm bearing service kit BGM ORIGINAL Race

As a rule, it is sufficient to stabilize the scooter (place it under the footboard and secure it with straps if necessary) and remove the engine from the front of the swingarm and then pull it slightly to the rear. Then there is enough space for all the work. An ideal job if the engine is to be overhauled anyway and is already on the workbench.

Yes. The service kit only affects the mounting of the engine in the frame and is independent of the variator, primary ratio or cylinder selection. The reinforced lateral guidance is a great advantage, especially for engines with greatly increased performance.

While some tuning mounts are very hard and improve lateral guidance but transfer a lot of vibrations into the frame, the BGM insert combines firm guidance with rubber-elastic damping. This keeps the handling precise without the scooter "rattling".

EPDM is significantly more resistant to weathering, UV light and ageing than classic NBR rings. Particularly in exposed areas such as the engine swing arm, EPDM rings remain soft and tight for longer - an advantage for anyone who regularly rides their scooter in all weathers.

Yes, it replaces worn standard parts with high-quality components at the original attachment points. For the MOT inspection, it is crucial that the clearance and condition of the bearings are correct - this is exactly where the BGM ORIGINAL Race service kit comes in.

DE | €

DE | €