Tuning kit including Kingwelle crankshaft and CNC cylinder head NAGY BLECHROLLER 135 cc

Suitable for Wideframe/Faro Basso 1948–1952, Ø=56.5 mm, stroke=54 mm – Vespa V1 to V15, V30 to V33, 125U, ACMA (-1953), Hoffmann A, B, C, M24, Douglas Rod

The tuning kit from NAGY BLECHROLLER is designed for the first engine generation of the Vespa Wideframe models from 1948–1952. These models feature so-called 1-port engines. They were used by Piaggio in the V1–15, V30–33 models, the economy model U125, and in licensed builds from Hoffmann Werke (A–C) as well as the British Douglas Rod models. The special feature of these engines is their unusual port layout by today’s standards. The cylinder has only one port each for intake, transfer, and exhaust.

Because of the single transfer port, this type is referred to as a 1-port engine (cross-flow scavenging). It can be identified from the outside by the exhaust and intake flanges sitting directly next to each other. These engines also feature a very short stroke of just under 50 mm, which results in limited torque in the lower rev range in stock condition.

DISPLACEMENT + RELIABILITY

This is exactly where the Nagy tuning kit comes into play. It was developed according to the simple but rarely implemented formula of displacement + reliability.

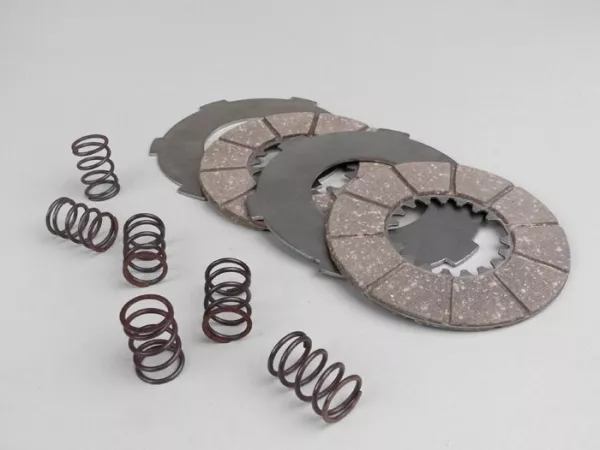

It consists of the following engine components:

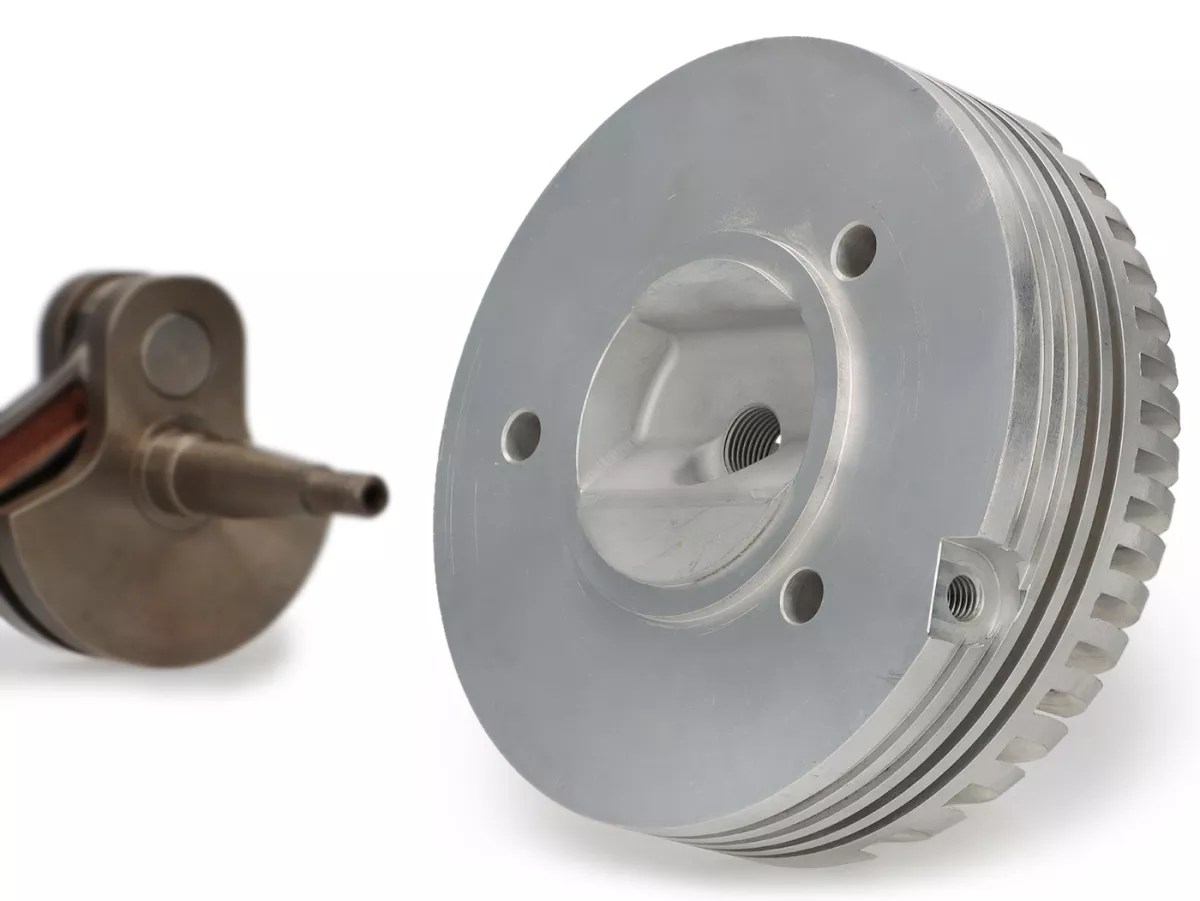

Crankshaft (54/110) with needle bearing piston pin

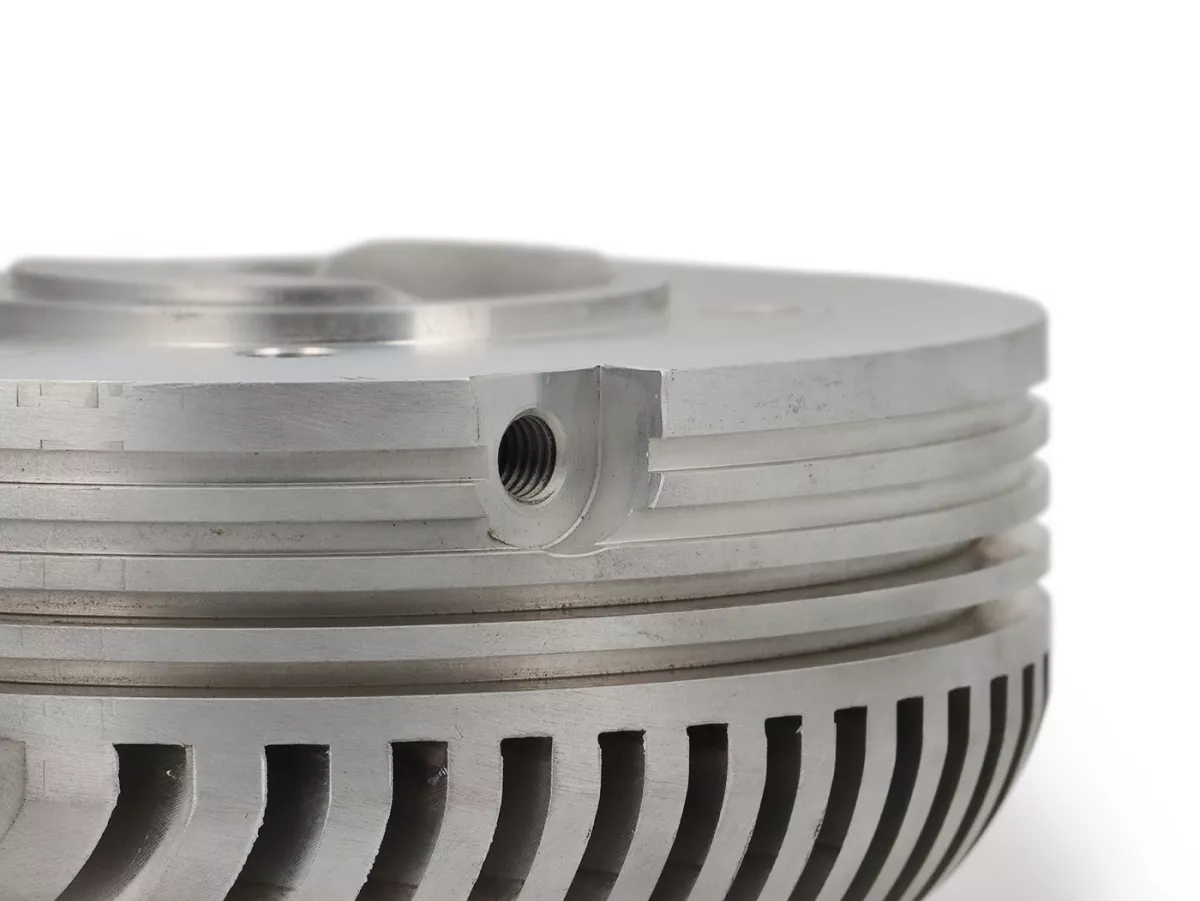

CNC-machined cylinder head with increased compression (1:8)

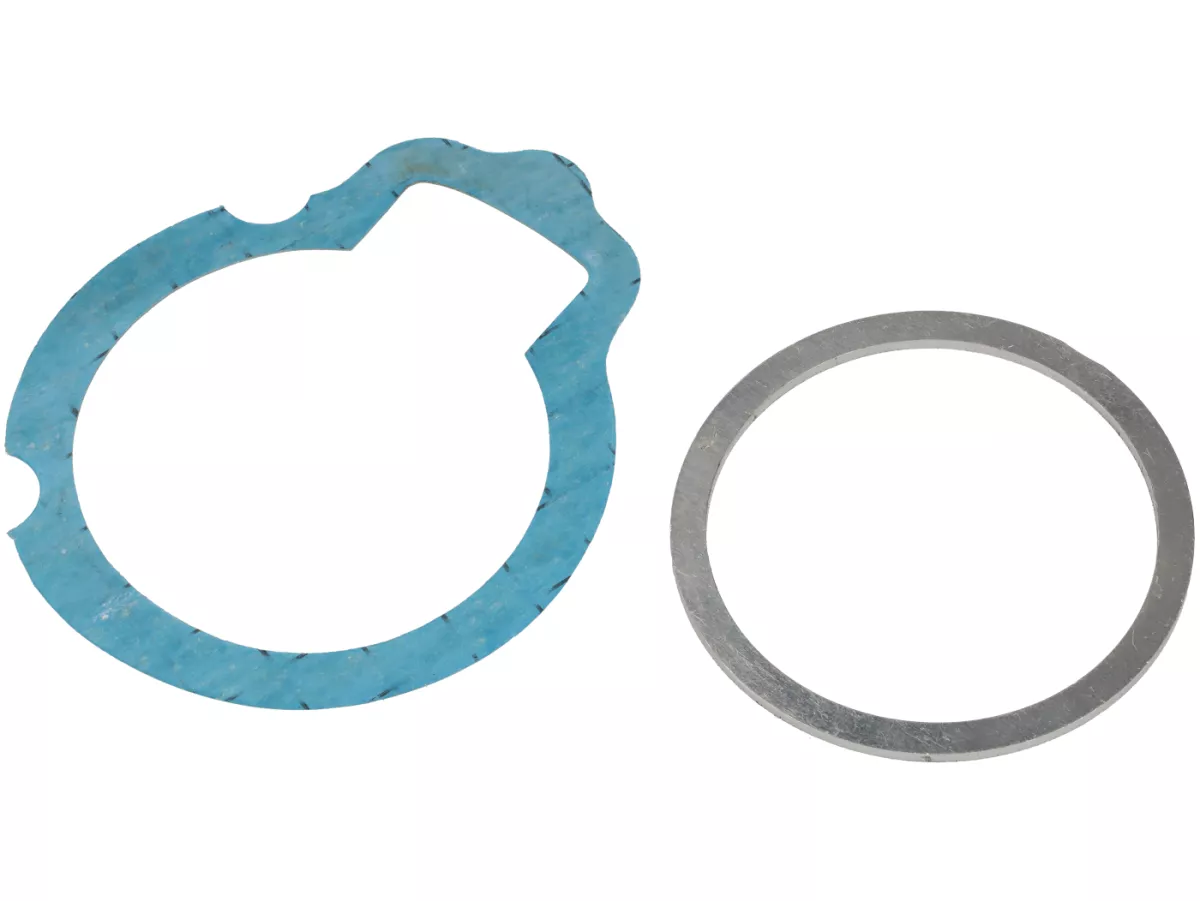

Base gasket (0.4 mm Aramid)

Head gasket (2 mm aluminium)

Porting template for modifying the exhaust port

MORE STROKE – Crankshaft by Kingwelle

The Nagy kit uses a premium crankshaft made in Germany by Kingwelle. Manufactured from extremely high-quality material with great precision, this crankshaft has a stroke of 54 mm. This not only increases the displacement to 135 cc but also significantly extends the port timings of the cylinder.

BREATHE FREELY – More port timing + exhaust adaptation

The stroke compensation is achieved via a spacer included in the kit. Since the port timings of the cylinder do not increase proportionally with the longer stroke (due to the trigonometric function, the transfer timing increases more than the exhaust), it is necessary to enlarge the exhaust port to increase the blowdown timing (i.e. the duration the exhaust port opens before the transfer ports). The included template ensures precise execution. This allows the cylinder to breathe much better and makes full use of the increased displacement.

CYLINDER HEAD – more compression made in Germany

The original engine has a stock compression ratio of only 6.5:1 (modern engines often have double that). This was due to the fuel quality at the time (72–74 RON) and the very uneven combustion chamber shape caused by the deflector piston. The Nagy tuning kit addresses this with a specially developed CNC-machined aluminium cylinder head. It raises the compression to 8:1 despite still using the deflector piston. Given today’s knock-resistant fuels and vastly improved 2-stroke oils (back then, plain motor oil was used), the compression remains conservative and guarantees excellent reliability. The solid CNC head also provides high thermal capacity – and while it disappears under the shroud, it looks great. Like the crankshaft, the head is manufactured in a German specialist workshop.

PERFORMANCE AND TORQUE

The longer stroke from the Kingwelle crankshaft combined with the adapted exhaust port results in the following port timings:

- Transfer: 117°

- Exhaust: 160°

- Blowdown: 21.5°

- Geometric compression: 8:1

With this configuration, the Nagy kit increases rear wheel power to 4.5 hp and a solid 9 Nm of torque – all while using the original carburettor and exhaust. The result is a noticeably more agile and torquey engine that handles climbs far more confidently than the stock engine, which barely delivers 3 hp at the rear wheel.

CONCLUSION

The NAGY tuning kit is not cheap. However, compared to the value of the vehicle and the top-quality tuning components made in Germany, it is more a necessity than a luxury – especially if the scooter is meant to be ridden regularly. A new crankshaft is a must for any 70+ year old engine anyway, and the riding fun will more than make up for the investment. A major benefit: the original cylinder and exhaust remain in place, so the conversion is visually and acoustically invisible.

DE | €

DE | €