Adapter plate set for converting Malossi 210 sports cylinder to Vespa 80-150 cm³ largeframe engine housing

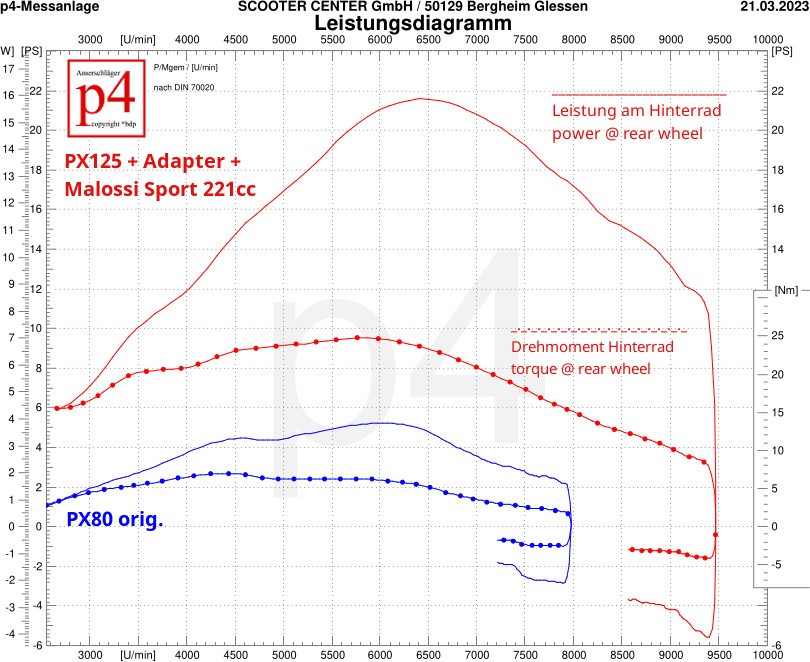

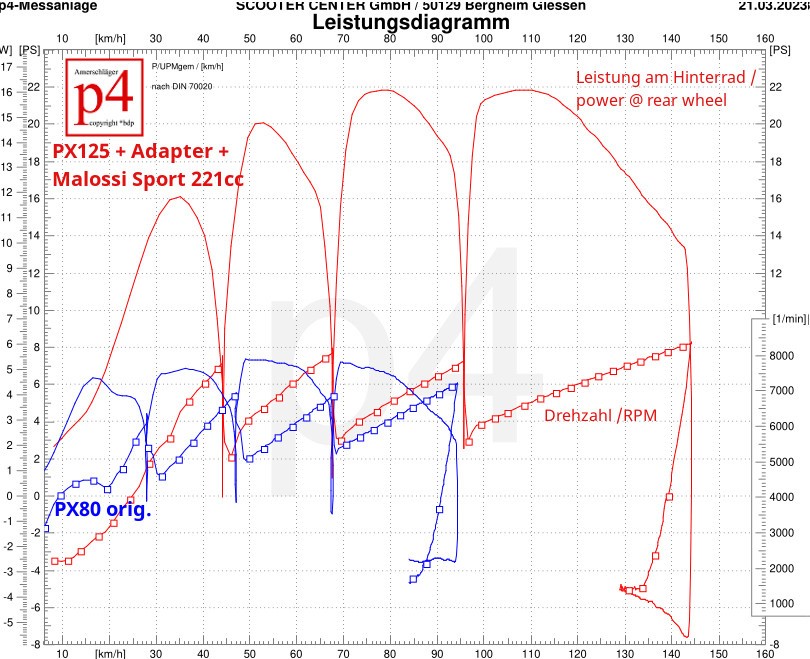

More torque and composure in everyday use and on the mountain pass, without a new engine case: This set allows the use of a Malossi 210 Sport cylinder in conjunction with a 60 mm stroke on largeframe engines from 80 to 150 cm³. The result is around 221 cc with very early, broad torque and stable running.

221 cc concept

High torque

Steel adapter plate

PX crankshaft 60 mm

For 3-channel housing

Scope of delivery adapter set

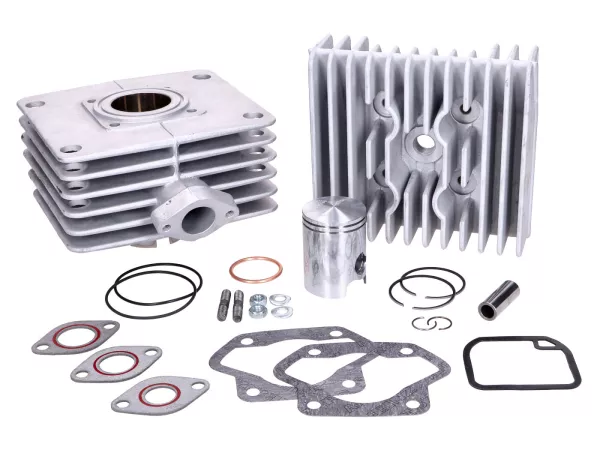

Malossi 210 cm³ cylinder incl. head (M3118591)

BGM031125G Crankshaft 60 mm stroke, connecting rod 125 mm

Adapter plate steel 14 mm

Aluminum spacer 1.5 mm

Four stud bolts M8 x 165 mm

Four screws M7 x 25 mm

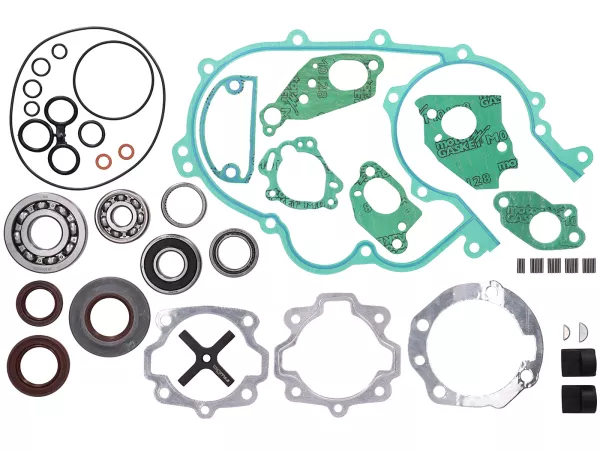

Additionally required

Exhaust from the PX200 series or comparable box

Longer gear reduction to suit the application

Reinforced clutch

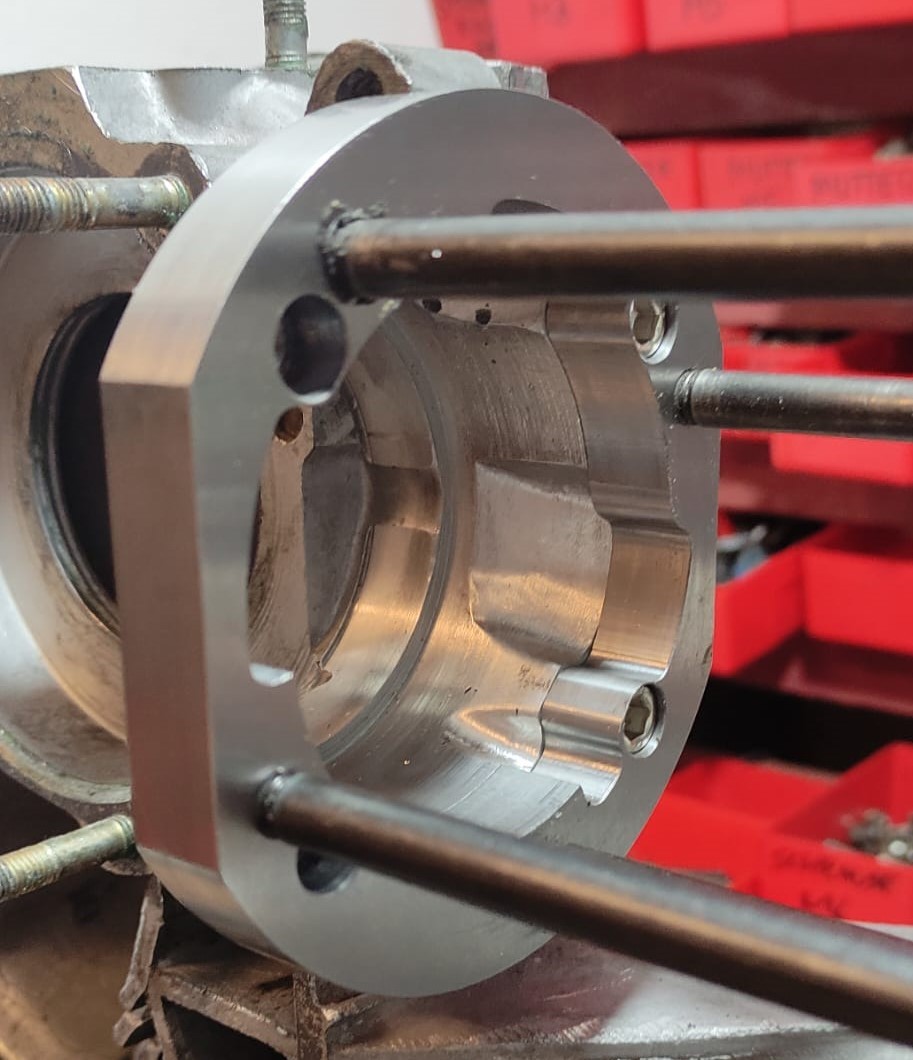

Necessary modifications to the engine housing

Spindle out cylinder base seat in engine housing to Ø 74.0mm.

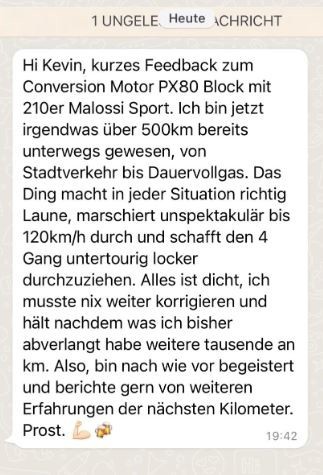

Malossi-Sport

The SC80210 set is designed for the Malossi 210 Sport. With an adapted housing, SI24 carburetor and a good box system, a very early onset of torque with a wide range suitable for everyday use is achieved. The combination has been in use for several tens of thousands of kilometers. We can therefore attest to its absolutely solid durability.

Crankshaft and intake

The BGM crankshaft fits in PX80-150 cm³ cases without modifications. The timing is matched to the intake layout of these housings. The engine operates very smoothly and powerfully even with moderate intake timing. Values around 115° before and 60° after TDC have proven themselves in tests. On the PX80 housings, these angles are not quite achievable due to the transverse milling in the rotary valve sealing surface (anti-manipulation measure of the 80cc class), but the higher flow velocity in the smaller intake window can overcompensate for this in this case.

Carburetor

We recommend the use of the standard carburetor of the PX200 models: SI24/24E. This comes with the appropriate jetting ex works and is a reliable companion. We offer this in a further revised form as the BGM Faster Flow carburetor. For the SI24, the passage in the carburetor bowl is slightly adjusted (file/Dremel/Proxxon).

Which primary combination makes sense?

Minimum: PX80 gearbox with longest available primary (25/62).

Touring and high-torque: PX125/200 gearbox with helical primary 64 or 65 and 24 clutch pinion.

The concept also reliably pulls longer primary reduction ratios.

Insider tip: straight-toothed 25/62 with auxiliary shaft 12-13-16-19. Longer gears 1 and 2, closer stepped connection 3/4, agile at the top and yet with a long ratio.

PX80 gearbox briefly explained

Overall ratio significantly shorter. Even with 25/62, the fourth gear lacks around 9 km/h or around 500 rpm compared to the PX200.

Smaller tooth module than PX125-200, increasing the risk of breakage of the narrower tooth profiles under high loads.

Recommendation: Conversion to the stronger PX125-200 gearbox, see notes below.

GEARBOX PX80

Conversion to PX125-200 gearbox

The PX80 auxiliary shaft differs in diameter from the 125-200 cm³ models.

Large housing half, clutch side: a bushing is usually fitted ex works which reduces the seat from Ø 13 to Ø 11.5 mm. This bushing is removed. The PX125-200 gearbox auxiliary shaft axles then fit.

Small housing half, alternator side: usually suitable if a Lusso auxiliary shaft axle with Ø 13 mm is already used on the auxiliary shaft stub on the Lima side.

Some older gearboxes still have Ø 11.5 mm on the Lima side. Here you can simply change to a conventional PX125-200 auxiliary shaft axle with Ø 13 mm.

Kick starter: use the pinion of the PX125-200, the kick starter segment remains in the housing.

Retaining the PX80 gearbox is possible, but remains a compromise due to the short overall gear ratio and smaller tooth module. If retained: use very long primary like 25/62 and stable Cosa-2 clutch.

TRANSMISSION PX125/200

Assembly instructions and tuning

Complete Lusso gearboxes are recommended.

Proven primary: helical 64 or 65 with 24 clutch pinion. Ideal if mainly used in city traffic and for leisurely country rides.

Long version: straight-toothed 25/62 with auxiliary shaft 12-13-16-19 for usable long lower gears and tight connection at the top. Results in a very usable engine that always has the ideal reduction ratio.

Clutch

Models 80-150 cm³ have the small 6-spring clutch until 1998. For the high torque of the 221 concepts, the Cosa 2 design makes sense. The BGM Pro Superstrong offers high stability with comfortable operation.

Ignition and pole wheel

Standard components can be used. The ignition timing is set between 18 and 23 degrees before TDC to suit the cylinder. In tests, the BGM Touring pole wheel weighing 2300 grams harmonized very well with the power delivery.

Cylinder cover

Due to the 14-15 mm increase in cylinder height, the hood must be extended. A simple solution is to combine two covers by adding sheet metal screws or plastic welding to the lower third of a cover. The more elegant solution is to use the spacer plate (item number SC802CL, see accessories)

Exhaust

Adaptation may be necessary due to the installation position. Box systems such as Polini sometimes require twisted mounting brackets, the BGM Touring V2 (BGM1011TR2) ran without any changes in the test.

Removing the cylinder when installed

With the cylinder raised, disassembly is limited when the engine is installed. Alternatively, the stud bolts are locked with the BGM72M7 tool and unscrewed from the adapter plate when the cylinder is fitted so that the head and cylinder can be removed from the frame. The steel thread of the adapter plate is not critical for this.

Durability

The original Piaggio engine cases are very sturdy, which means that they can withstand the set permanently without any problems (cast wall thicknesses are identical to the 200cc cases). An exception are the rebuilt LML 5-channel engine cases (e.g. from RMS). These have thinner walls in the cylinder base area, which means that conversion is only possible by welding on material.

Conclusion

With manageable effort, a powerful, durable 221 concept can be created from an existing 80-150 cm³ large-frame engine without having to change to a new housing. The combination offers early torque, long gear ratios and high suitability for everyday use.

Compatible vehicles

Sprint Veloce 150 (VLB1T from 294260)

GTR 125 (VNL2T from 145901)

Super 150 (VBC1T from 412374)

TS 125 (VNL3T from 18139)

PX80 (V8X1T), PX125 (VNX1T, VNX2T, ZAPM093), PX150 (VLX1T, ZAPM74, ZAPM094)

Cosa 125 (VNR1T), Cosa 150 (VLR1T)

LML 125/150 2-stroke

Star and Stella 125/150 2-stroke

FAQ

Yes, the cylinder base seat is machined to Ø 74.0 to 74.1 mm. If you are looking for a set in which the existing 125-150cc housing can be converted to 200cc without spindling, use SC80200SET2. Here, a shortened original PX200 cylinder is used, eliminating the need for spindling (with the exception of the PX80).

Possible, but not recommended due to the short overall gear ratio and smaller tooth module. It is better to convert to a PX125-200 gearbox, see chapter GEARBOX PX80.

On PX125/200 secondary gearboxes: Helical gearing 64 or 65 with 24 clutch pinion is a robust, torque-friendly solution. The concept can also pull longer ratios, such as 25/62 straight-toothed in combination with a 12-13-16-19 auxiliary shaft.

On the clutch side, remove the reduction bush from Ø 13 to Ø 11.5. On the limousine side, no machining is normally required when using a Lusso gearbox with Ø 13 mm. Older 11.5 mm auxiliary shafts are replaced by a Lusso axle with 13 mm.

Video:

DE | €

DE | €