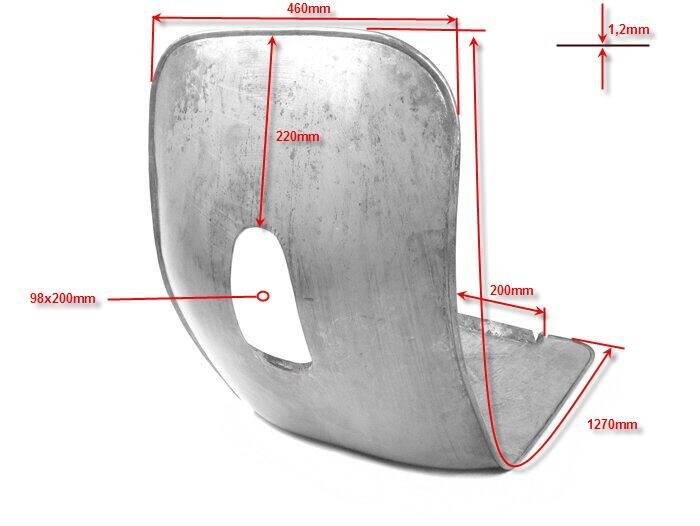

Leg shield and floor plate for Vespa Sprint, Rally, GL, GT, GTR, SS180, Super - custom-fit repair parts in premium quality

We are now finally able to offer repair plates for the leg shield and floor plate for the Vespa Rally / Sprint models, which are now quite expensive. Very often the frames of these models are heavily infested with the brown plague in the area behind the mudguard. Although the frame is usually still visually intact on the outside, it is almost completely rusted through on the inside. A doubled sheet of metal on the inside keeps the moisture in place and allows the frame to slowly rot through. This has already caused several frames to be scrapped or cost many hours of work armed with tin snips and welding equipment, provided you have the skills to carry out such work yourself.

Now there is a quick, inexpensive and high-quality solution to restore the frame to perfect condition.

A complete leg shield including the corresponding base plate enables rapid restoration progress to be made without having to learn the tinsmith's trade first. The coachbuilder will not only be grateful, but will also be able to present a much smaller bill, as he can work much more quickly.

The well-fitting panels are a 1:1 match to the original, with the exception of the upper part of the horn cascade. This is pressed into the leg shield plate in the original, whereas the repair plate here is smooth. We therefore offer this part of the cascade separately, with the advantage that you can choose between two versions (hexagonal or rectangular logo). The lower part of the cascade is currently only available in the Italian version with the small horn opening.

In the original, a plate is doubled in the inner radius of the transition from the floor plate to the leg shield in the middle of the tunnel to additionally reinforce the chassis. This should be made by hand to make the restoration complete and perfect.

The leg shield is made of black plate and is stored by us treated with anti-corrosion grease.

Tip: We recommend assembling the scooter in its unfinished state once before each paint job, a so-called dry-build. This allows any necessary adjustment work to be carried out quickly and easily without damaging the new paintwork. This makes assembling the freshly painted parts twice as much fun!

DE | €

DE | €