SC CLUTCH - The little brother of the BGM Superstrong clutch for Vespa PX

High-quality BGM PRO components in the standard clutch basket. Combines all the advantages of the Cosa2 clutch type at an unbeatable price:

- Very easy to pull

- Separates very cleanly

- Fast and precise gear changes

As a further special feature, the SC clutch is available with special pinions to shorten/lengthen the original transmission ratio.

FITS

The SC clutch replaces any conventional clutch type as used in Vespa largeframe models with rotary intake valve control from approx. 1956 onwards. Can therefore be used in Vespa VNA, VNB, VBA, VBB, T4, GL, Super, Sprint, Sprint Veloce, GT, GTR, TS, Rally, PX, Cosa and T5. Fits all vehicles from 1995 onwards and engines from 180cc (ex works), Vespa T5 and all Cosa models without modifications.

MODIFICATIONS

Vehicles with less than 180cc (ex works) require the clutch cover for 200cc models unless the original clutch cover is to be modified. Vehicles built before 1995 must be minimally modified to fit the Superstrong clutch (see documents under Downloads).

APPLICATION RANGE

Ideally suited for original and slightly tuned engines. For applications above 15 hp, we recommend the BGM Superstrong clutch.

EQUIPMENT

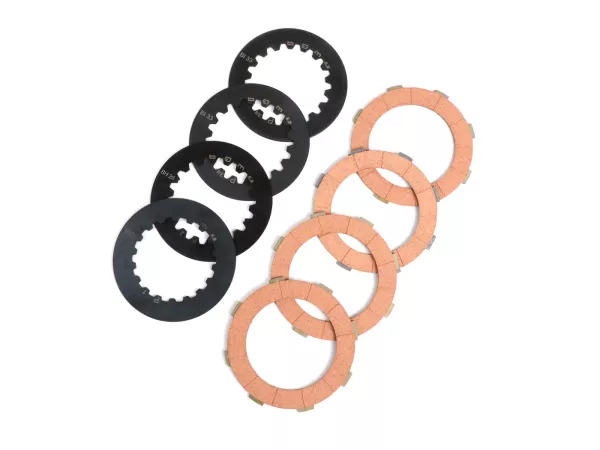

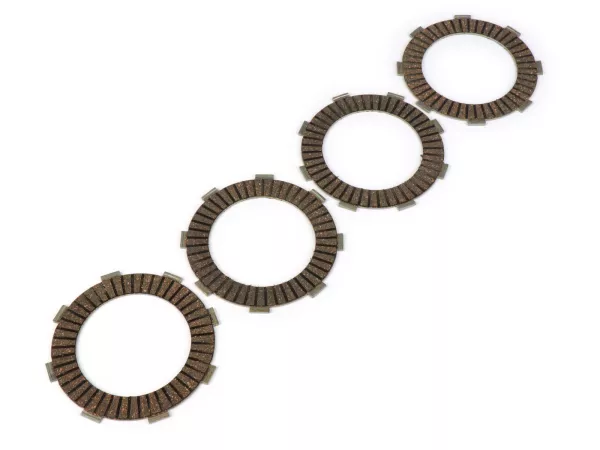

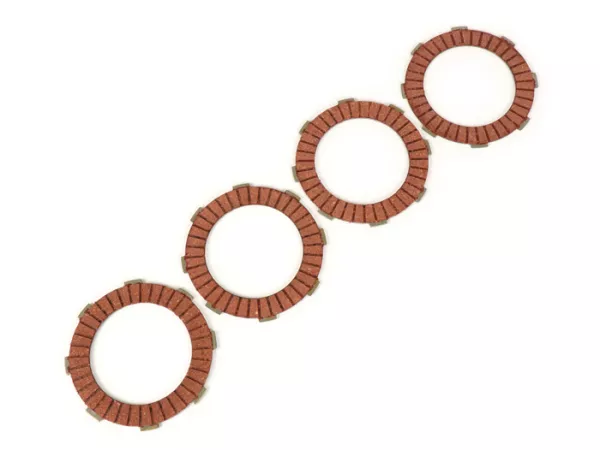

The SC clutch is equipped with: BGM PRO retaining ring (reinforced), BGM PRO reinforced clutch springs (8 pcs. XL), BGM PRO clutch pinion, BGM PRO clutch facings, BGM PRO steel plates

MANUFACTURING

The SC clutch types are all manufactured and tested by hand in-house for maximum quality control.

TRANSMISSION

A primary drive consists of a clutch (pinion) and primary wheel. Piaggio has already combined 65, 67 and 68 tooth primary gears with different clutch pinions ex works. This makes it easy to adapt the overall gear ratio to the engine power. A distinction is made here between 67/68 and 65 teeth. Due to the different so-called gear wheel module, the following wheel/pinion combinations can be used.

Please note: BGM is the only manufacturer to offer different 22T pinions for 67/68T and 65T primary gears. This is the only way to guarantee maximum stability.

|

Primary sprocket

|

Primary sprocket originally installed in

|

Usable SC clutches

|

|

62Z*

|

x

|

23T*, 24T*, 25T* (straight-toothed)

|

|

63Z*

|

x

|

23T*, 24T*, 25T* (straight-toothed)

|

|

65Z

|

Rally200, PX200

|

22T*, 23T, 24T*

|

|

67Z

|

All 125-180cc models up to 1977

|

20Z , 21Z , 22Z, 23Z*

|

|

68Z

|

All 80-150cc models from 1978 onwards, all Cosa

|

20Z , 21Z , 22Z, 23Z*

|

*BGM sprocket with special module!

EXAMPLES

Longer gear ratio:

- PX80/PX125 riders use a clutch with 22 or 23 teeth (suitable for primary wheel 67/68) to extend the gear ratio.

- PX200/Rally200 riders use a clutch with 24 teeth (suitable for primary wheel 64/65) to extend the gear ratio.

Shorter gear ratio:

- PX200/Rally200 riders use a clutch with 22 teeth (suitable for primary wheel 64/65) to shorten the gear ratio.

RELATIVES

Clutches with straight-toothed sprockets can only be combined with the corresponding straight-toothed primary wheel. The engine must be fully opened for this purpose. The extra-long primary reduction gears based on the 62/63-tooth primary sprocket are only available with straight teeth. The high torque of the motors, which require such a long reduction ratio, is transmitted directly to the gearbox via straight teeth without exerting lateral forces on the bearing of the auxiliary shaft. Thanks to the precision manufacturing, the straight-toothed drives are nevertheless just as quiet as the helical-toothed drives

.

TIP

For the widest possible gear ratio range, simply install the special BGM 64-tooth primary gear (the motor must be completely opened for this). The engine can then be geared up to a torque steamer by simply changing the clutch pinion

.

XTRA

LONG

Engines with a lot of torque and an early power peak choose the straight-toothed clutches, which also require a straight-toothed primary gear (also available as a set). This allows very long reduction ratios to be achieved. Ideal, even if the overall gear ratio is too short for very sporty engines with a modified auxiliary shaft and shorter gear steps. Also an option if the actual gearbox is very short (PX80) or the gear ratio is too low due to a small wheel diameter (PX200 engine with 8 inch tires in oldie).

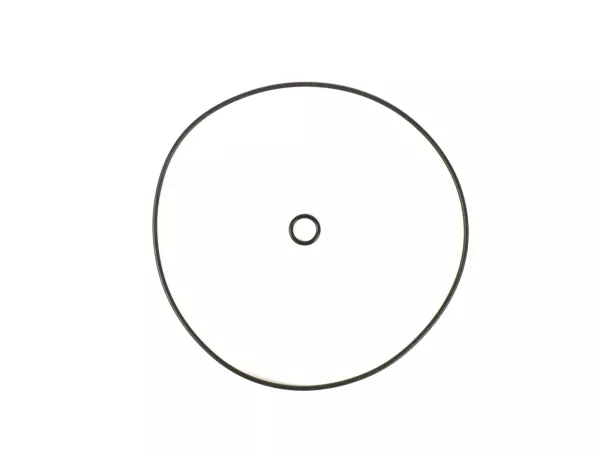

SCOPE OF DELIVERY

The scope of delivery includes the complete ready-to-install clutch with bgm PRO Cosa clutch facings and eight BGM PRO XL springs. A new O-ring for the clutch cover, the half-moon wedge and a new clutch nut are also included. We use a nut with clamping part (MBN13023, T2, strength class 10, DBL9440.40), as we have had the best experience with this nut in racing with over 40 hp shaft power. Tightening torque 70-75NM. We do not recommend other locking devices such as Nordlock, corrugated spring washers (DIN137) or serrated lock washers (DIN6798).

We recommend BGM Pro Street gear oil (BGM2025, corresponds to API GL-3 specification) as a lubricant.

(US111218)

DE | €

DE | €