Postage free from 99€ (DE)

High customer satisfaction

Shipping today with order in 11 h 7 min

- Vespa Classic

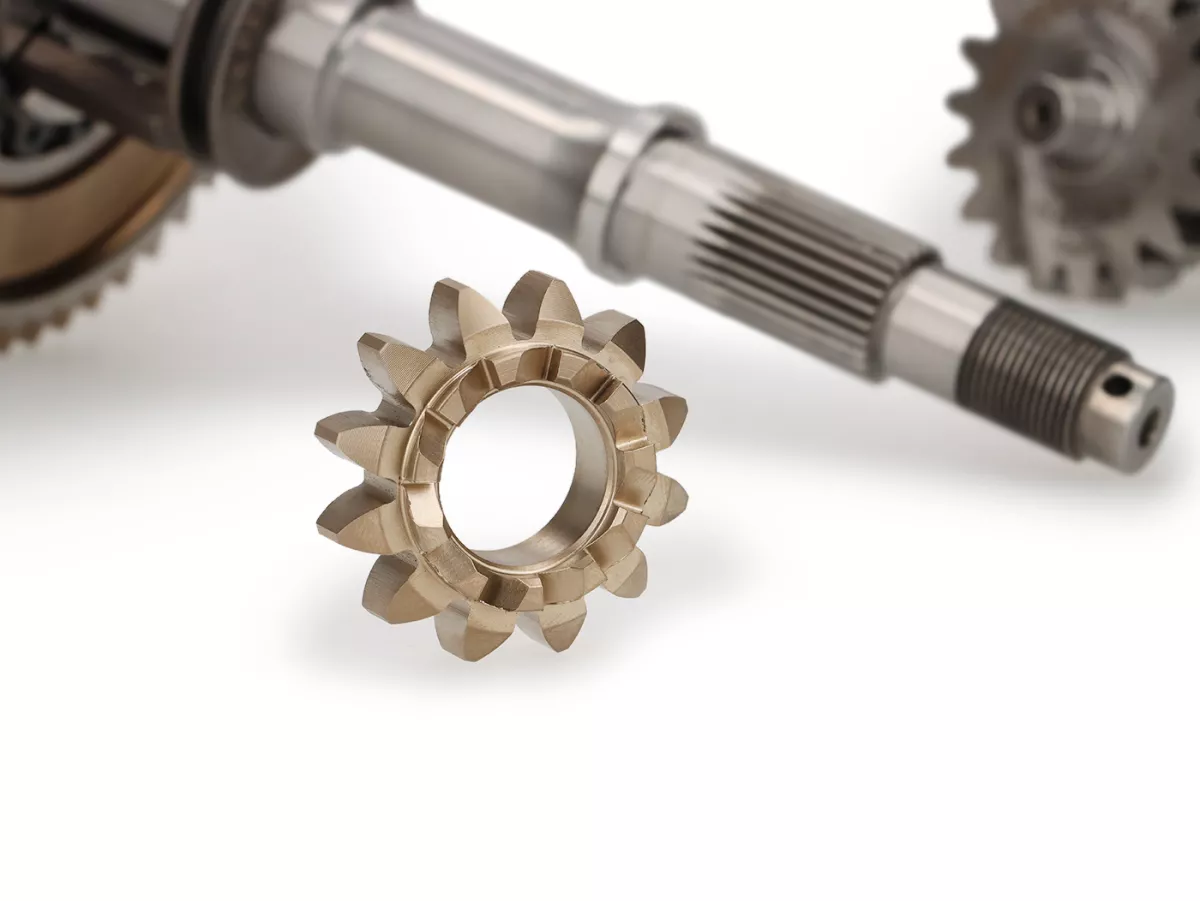

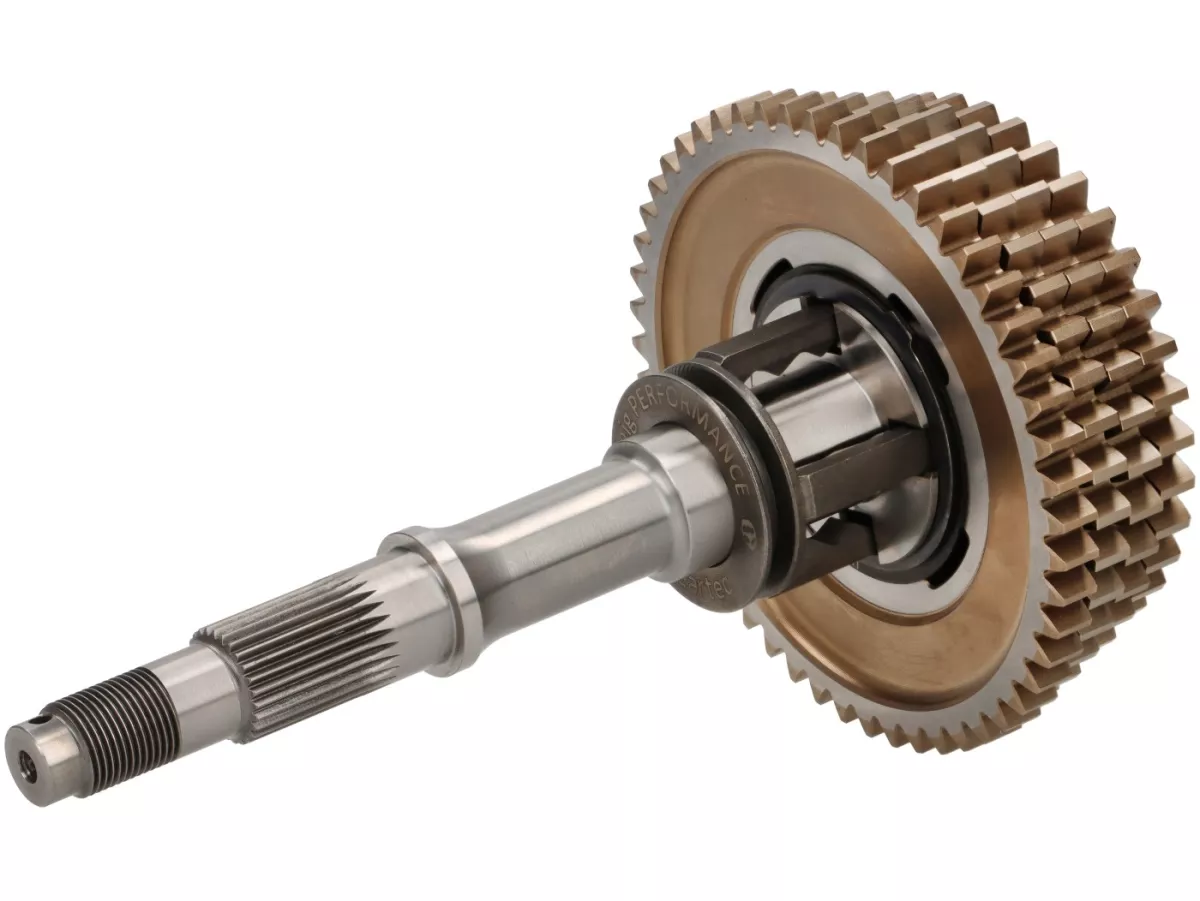

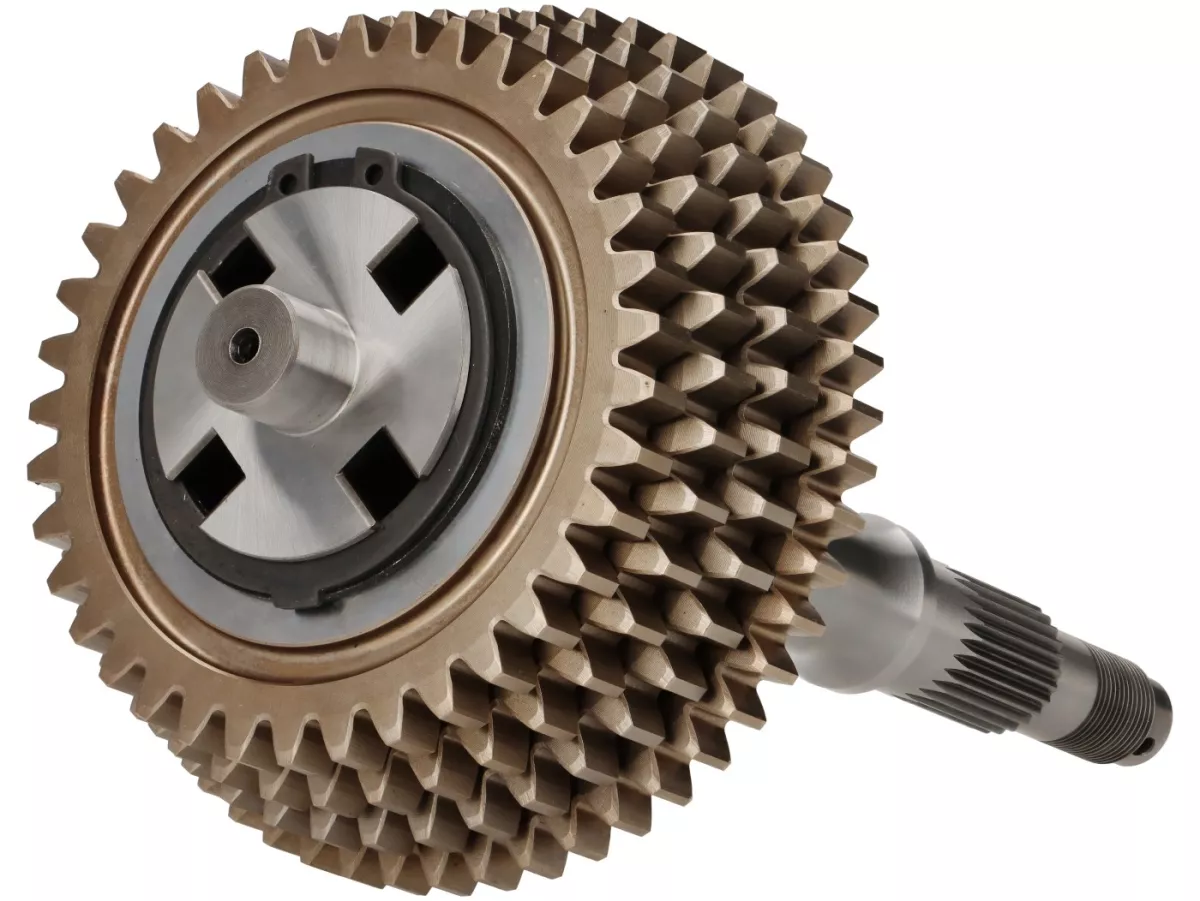

- Complete gearbox (gears incl. main shaft + auxiliary shaft) for Piaggio housing -EGIG/FAIO X-TRA STRONG, CNC drive shaft - Vespa Smallframe V50, PV, ET3, PK, HP 4-speed- 18/37-15/38-12/42-10/52 - auxiliary shaft with cone

DE | €

DE | €