Postage free from 99€ (DE)

High customer satisfaction

Shipping today with order in 12 h 4 min

-

all

Tip of the day

-

Vespa Classic

-

Vespa Modern

-

Moped classic

-

Lambretta

-

Scooter 50-850cc

- Lambretta

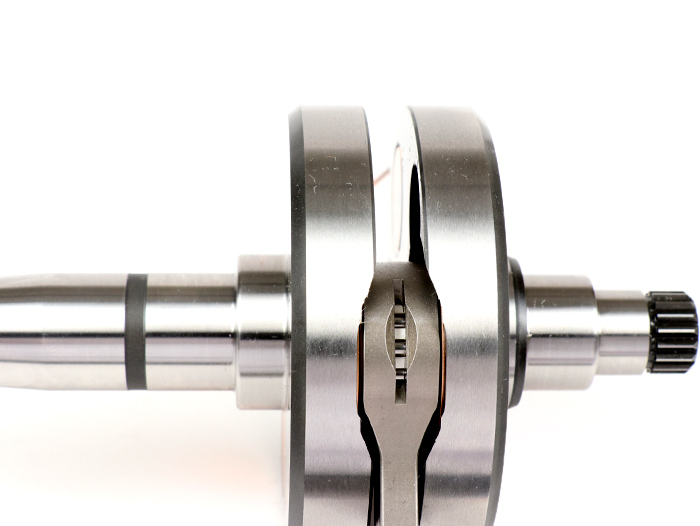

- Crankshaft -BGM Pro HPC Competition 58mm stroke, 107mm conrod- Lambretta DL/GP 125cc, 175cc, 200cc, 225cc, 250cc

DE | €

DE | €