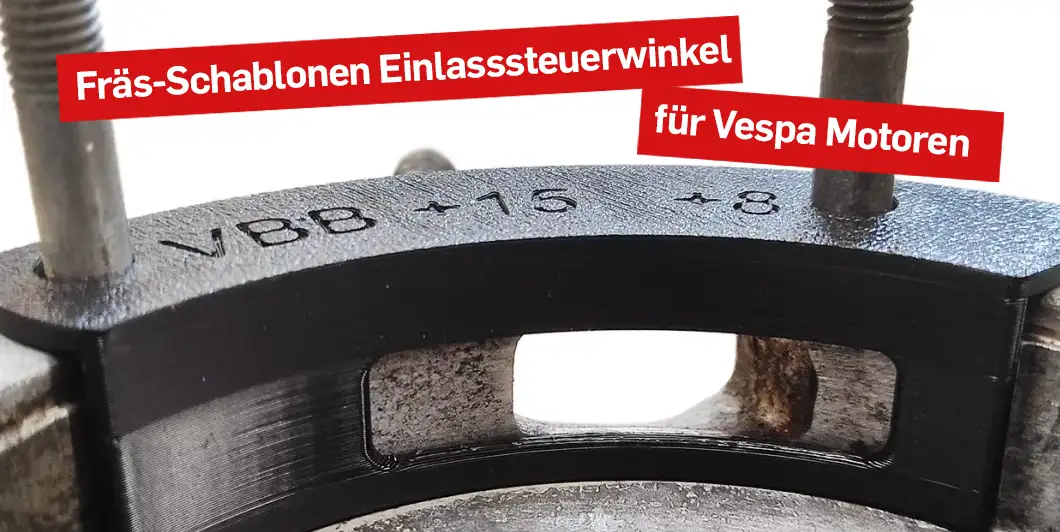

Milling template rotary valve - bgm PRO intake optimization for Vespa PX & Co.

With the bgm PRO milling template, you can get the maximum torque out of your Vespa large-frame engine from the PX, LML or Sprint Veloce series - safely, precisely and suitable for everyday use. Developed for classic 3-channel engines from 1977 onwards, it enables targeted optimization of the intake timing - without any risk to the sensitive sealing surface.

Why optimize?

In many tuning setups with more displacement or increased torque, the standard intake port limits the potential of your engine. The bgm PRO template helps you to eliminate this bottleneck:

✅ Noticeably more torque: extended control angles fill the cylinder better

✅ Tested suitability for everyday use: No experiments - ideally tuned for touring setups

✅ Controlled machining: The template sets clear limits for depth and width

✅ No damage to the sealing surface: safety is maintained

Technical basis

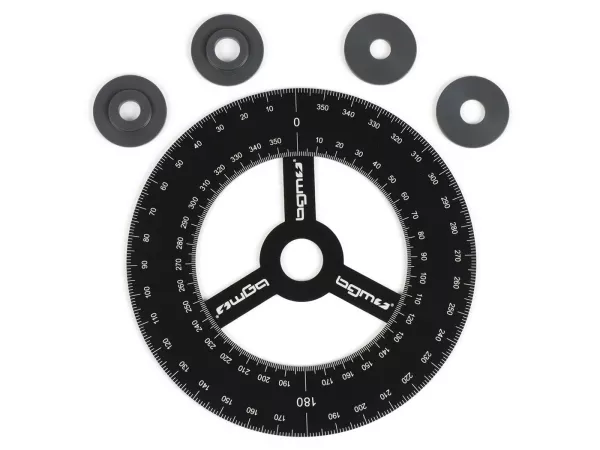

The bgm PRO template was developed on the basis of numerous engine setups. It is aimed at riders who want to optimize their Vespa - whether for city, country road or touring. The recommended steering angle combination (approx. 110°/55°) provides powerful acceleration for everyday use and can be perfectly tuned with the SI carburetor and touring exhaust. Of course, the steering angles can also be individually adjusted (see info box below). Depending on the crankshaft used, the overall intake control angles of the intake vary greatly. A Polini crankshaft has significantly more intake angle after top dead center (TDC) than a BGM touring shaft, for example. To be able to measure the entire opening angle, you need a degree meter (see accessories). The template has the advantage that it is already optimized for use with a BGM crankshaft.

Note: PX80 engine cases usually have cross holes in the sealing surface of the rotary valve inlet. This means that they cannot be opened as wide at the intake as the unthrottled PX125-150 cases without further modifications. If the transverse cut-outs are closed, this valve can also be used on the PX80.

Suitable for the following engine housings

Largeframe 3-channel (from 1977): PX125, PX150, LML 2T, Sprint Veloce

FAQ - Frequently asked questions about the Vespa intake control angle milling template

| Question | Answer |

| Do I need special tools? | No. A file is sufficient. It is quicker to use a small hand router (e.g. Dremel or Proxxon). |

| Can I damage the sealing surface? | No. The template takes full account of the safety of the surface. |

| Is the whole thing legal? | The optimization is classic Vespa tuning - use on the road at your own risk. |

| What are the benefits in practice? | More torque, better acceleration, possibly even lower consumption - with the same reliability. |

Touring vs. sport - finding the right setup

Touring setup (recommended for everyday use & touring):

✅ 110-115° from TDC

✅ 50-65° from TDC

➡ Ideal for sporty touring engines, SI carburettors (20-26 mm), box exhaust systems

Sport setup (for ambitious conversions):

✅ 120° from TDC

✅ up to 75° from TDC

➡ For setups that want to get the maximum out of the rotary valve, ideal with Ø28-30 mm carburetor, racing cylinder & good box exhaust or even resonance exhaust. In combination with the longer intake path due to a larger carburetor (due to the different intake manifold then required), no problems even in the very low rpm range.

DE | €

DE | €