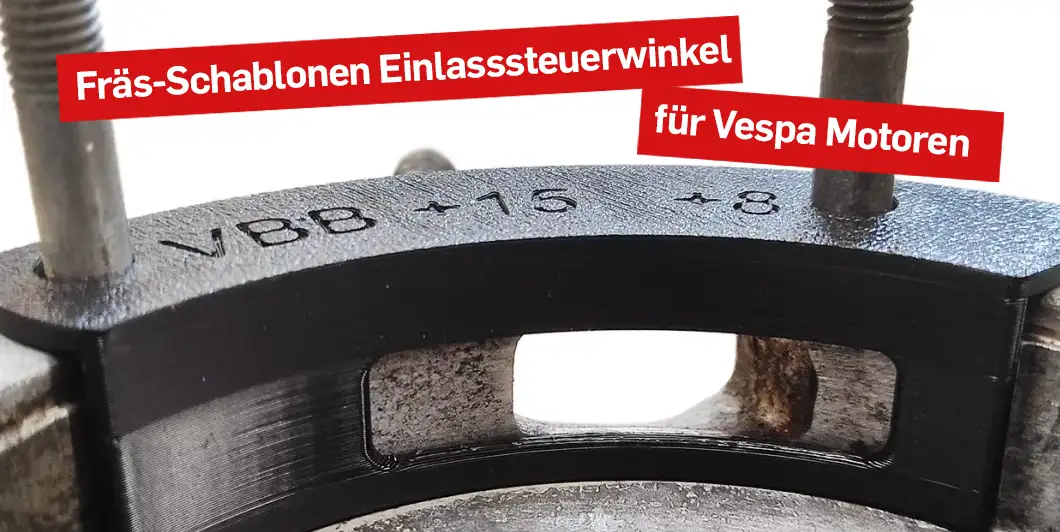

More power for your Vespa - with the bgm PRO milling template for rotary valve intakes

After a tuning with more displacement and a powerful cylinder, Vespa engines simply lack one thing: sufficient intake area. Especially with older rotary valve engines, the original timing angles are extremely tame. If you want more torque and power across the entire rev range, there is no way around targeted machining of the intake.

Why use the bgm PRO milling template?

With the bgm PRO milling template, you get a precise tool to optimize your intake cleanly and for everyday use. The template was specially developed for typical touring setups and helps you to extend the intake times sensibly - without risking the sensitive sealing surface.

Easy to use

Especially if you don't regularly work on engines, there is often a lack of certainty as to how far you can actually open the intake. Our template provides you with clear guidance: it shows how far the intake can be machined in width and depth without making unnecessary compromises in terms of reliability and suitability for everyday use.

Technical background

As the width of the intake window is limited by the crank web, the control angle must inevitably be increased for more power. For maximum filling and noticeably more torque, it is therefore accepted that the intake times are longer than originally planned - a deal that is absolutely worthwhile when riding. The values recommended by us deliver strong torque with high everyday suitability, even with an SI carburettor.

No disadvantages - only advantages

The new intake area offers you noticeable advantages: better filling of the cylinder, more torque across the entire rev range and therefore significantly more riding pleasure - without any compromises. Anyone thinking of possible disadvantages can rest assured: The extremely conservative ex-works intake times on Vespa engines were originally designed for scenarios that hardly ever occur in everyday life today.

Piaggio also had extreme situations in mind at the time - the engines had to be suitable for even the most inexperienced rider and still work even with poor fuel or defective shaft seals. Such "worst-case conditions" no longer occur with today's lovingly maintained vehicles. A modern, well-tuned Vespa tourer today runs on the best fuel, with regular servicing and a properly adjusted setup. This means: The new steering angles bring you advantages - without disadvantages.

Our milling templates are precisely tailored to this modern purpose: suitable for everyday use, high-torque and economical - perfect for touring, city traffic or the next Vespa vacation.

Example:

VBB-Motors with BGM177

With a modified VBB engine and a bgm 177 ylinder in 2-channel version, over 16 hp / 12 kW are possible on the bike - with SI24 carburetor and touring exhaust. The difference to the original is striking. What's more, it remains fully suitable for everyday use.

How it works - step by step

- Measure the actual condition of your engine in conjunction with the selected crankshaft using the degree meter.

- Example VBB:

- Intake opens at 95° before TDC

- Intake closes at 46° after TDC

- Total angle: 141°

3. transfer the values of the milling template (e.g. +15° before TDC and +8° after TDC)

4. new angle: 110° before TDC / 54° after TDC =

159° total steering angle

Especially with older housings (e.g. VBB with 2-channel), a stud bolt blocks the path to the front - the after TDC values are realistically between 50° and 60°

.

Touring vs. sport setup

Touring

For a touring setup suitable for everyday use, we recommend a steering angle of 110-115° before TDC and 50-65° after TDC. These values deliver maximum power in the 5500-7000 rpm range - perfect in combination with an SI carburetor (20-26 mm) and a touring/box exhaust.

Sport

If you like it sportier, choose 120° from TDC and up to 75° TDC. This significantly increases the top performance - but also the demands on the carburetor (up to 30 mm), cylinder and exhaust. Ideal for PX chassis with extended intake path. There are three different lengths of rotary valve faces for Vespa Smallframe engines - the long versions of the PK125/HP models are best suited.

Available for many engine housings

- 2-channel largeframe: VNB, VBB, VGLA, VGLB, VNC, VLB

To the product

- 3-channel largeframe: Sprint Veloce, PX125/150, Rally 175/180, LML 125/150

To the product

- Ciao: And because you asked for it also for ciao!

To the product

Coming Soon!

- PX200 & Rally 200: Own template due to wider rotary valve

- Smallframe: PK, V50, ET3, PV

Conclusion

The bgm Pro milling template is the ideal tool for anyone who wants to get the most out of their Vespa engine - without sacrificing suitability for everyday use, economy or reliability. Whether touring setup or sporty conversion: With the template, you can enter the world of optimized intake timing safely and precisely.

DE | €

DE | €