BGM PRO 190ccm Powerpack for Vespa PX125/150 – more power & maximum reliability

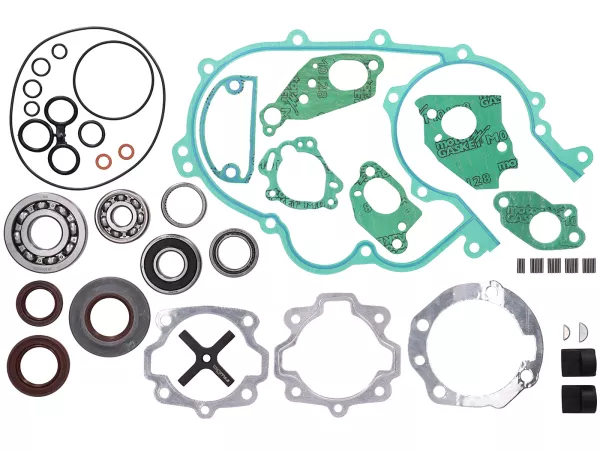

The BGM 190ccm tuning kit consists of two proven components: the now thousands of times proven BGM177/190 cylinder and the robust and reliable BGM Touring crankshaft with extended stroke (60 mm instead of 57 mm).

Together they form an extremely harmonious unit that is both very powerful and ultra-reliable. The BGM cylinder was designed from the outset for optional use with a long-stroke crankshaft. The longer stroke of the BGM crankshaft is compensated for by a head gasket spacer included in the kit. The result is ideal port timing for a powerful touring engine.

Simple bolt-on conversion – perfectly matched

The kit can be installed as a pure bolt-on tuning, i.e. without milling or modifications, on any PX125/PX150 engine (and similar engines such as LML or older Vespa engines like Sprint150 Veloce, GTR125). With a suitable exhaust, such as the perfectly matched BGM BigBox Touring, it easily surpasses the performance of a Vespa PX200. A solid 13–15 hp is already achieved at the rear wheel (original PX125 approx. 5–6 hp), allowing for very brisk acceleration and cruising at well over 100 km/h, depending on the chosen gear ratio.

Optional tuning stages – up to 19 hp for everyday use

If you want to access more power right from the start, this can be achieved with simple modifications. 16–19 hp is easily possible by simply adjusting the transfer ports (see our video tutorials on our YouTube channel) and matching the intake and carburettor from the 200cc models (SI24/24E). The engine remains as reliable as a stock engine, as the rpm stays within the stock range. The quality and durability of the materials used also allow for sustained full-throttle operation without issues.

Fuel consumption remains very moderate for this performance level, between 3.5–4.5 litres.

Noise levels also remain pleasantly low, thanks to the moderate rpm range.

Optimal gear ratios for touring & motorway riding

For engines primarily used in city and touring conditions, it is sufficient to extend the gear ratio with a 23 tooth clutch gear (23/68 = 2.95).

For those aiming for high top speed or who want to ride on the motorway at lower rpm, a completely revised primary ratio can be used. We recommend the BGM primary gear for the PX200 with 65 or 64 teeth.

This also fits the secondary shaft of PX125/150 models. Together with a matching BGM clutch gear with 22, 23 or 24 teeth, you have a full range of gear ratios to choose from. A 23/64 primary ratio has proven to be a very good choice.

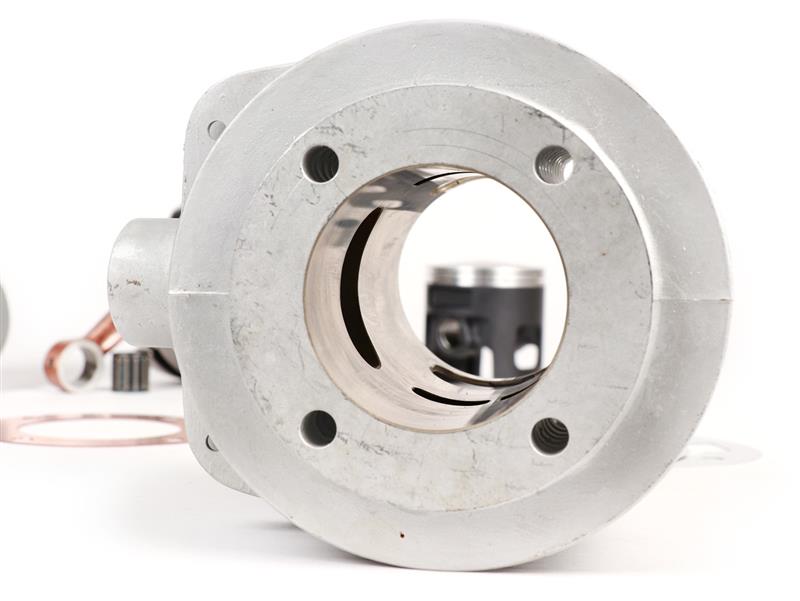

BGM PRO 177 cylinder – robust & torque-strong

The BGM PRO 177 cylinder is a hard ceramic coated aluminium cylinder with a 63 mm bore. The coating (Nickel-Silicon-Carbide) provides an extremely hard and durable running surface. The piston has a high silicon content, resulting in lower thermal expansion, greater wear resistance and excellent thermal stability. Two 1 mm thick piston rings minimise friction, increasing power and rev capability. The cylinder’s port layout with four main transfer ports and two boost ports is designed to provide strong low-end torque.

- Cylinder material: aluminium

- Running surface: coated with Nickel-Silicon-Carbide

- Bore: Ø 63 mm

- Displacement at 60 mm stroke: 187 ccm

- Piston: cast piston with high silicon content and two 1 mm steel piston rings

- Recommended squish clearance: 0.8–1.2 mm

Port timing

- 60 mm stroke: transfer ports 123°, exhaust 173° (with 0.2 mm base gasket, 1.5 mm head spacer)

The transfer ports at the cylinder base have a cast-in guide. This matches the cylinder ports to the engine casing. The guide can be easily removed to fully open the port cross-section.

The cylinder head is CNC machined from solid material. The combustion chamber is recessed 4 mm deep into the cylinder for perfect centring.

This also greatly facilitates setting the squish clearance and ensures a perfect seal. The centre of the head features a threaded hole for fitting a temperature sensor.

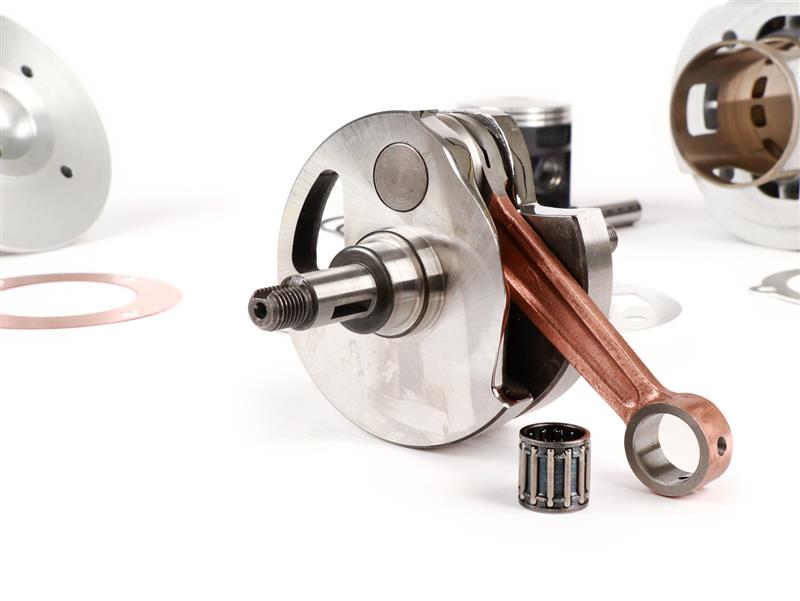

BGM PRO Touring crankshaft – maximum stability & perfect intake timing

MATERIAL

The BGM PRO Touring crankshafts are forged. The denser material provides better heat dissipation and higher resistance to distortion. Both the crank webs and the connecting rod are forged and CNC machined.

BEARING

The lower big end bearing is lubricated via two large oiling slots and four additional side pockets. The SSC racing bearing and side thrust washers ensure solid bearing support. The upper small end bearing is lubricated via two oil holes. The INA gudgeon pin bearing is included with the crankshaft.

INTAKE TIMING

The BGM PRO Touring crankshaft has a significantly better intake timing layout compared to many racing crankshafts. Standard crankshafts often have too short intake timing for tuning cylinders. The BGM PRO crankshaft closes the intake on a PX engine casing at approx. 58° after TDC (varies depending on casing). The engine can be easily tuned with these timings. Tip: If the intake is modified so the crankshaft opens it earlier, even more power can be gained. Around 120° before TDC has proven to be a good value.

Conclusion: maximum torque & everyday usability in a perfect package

The combination of the BGM PRO crankshaft and BGM PRO cylinder is an excellent choice in every respect. Top quality in every component. Precision manufacturing and materials deliver high and sustained performance. All this at an unbeatable price-performance ratio!

DE | €

DE | €