MATERIALThe

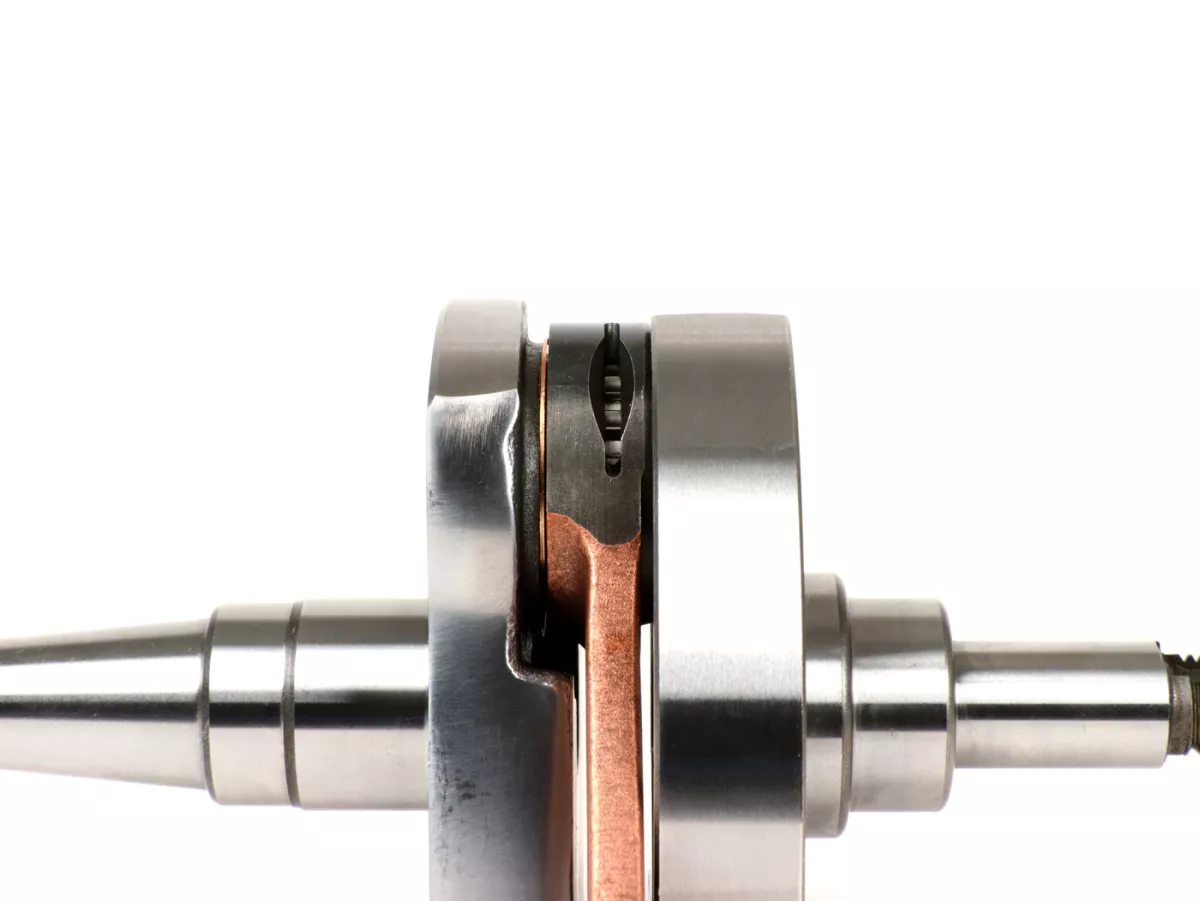

bgm PRO Touring crankshafts are forged. The material is highly compressed by the forging process. Structurally, it is therefore many times more resilient than conventionally manufactured cheeks made from 'bar stock'. We use this high resistance to increase the interference fit of the crankpin and to be able to offer a crankshaft with maximum torsional rigidity

.BEARINGS

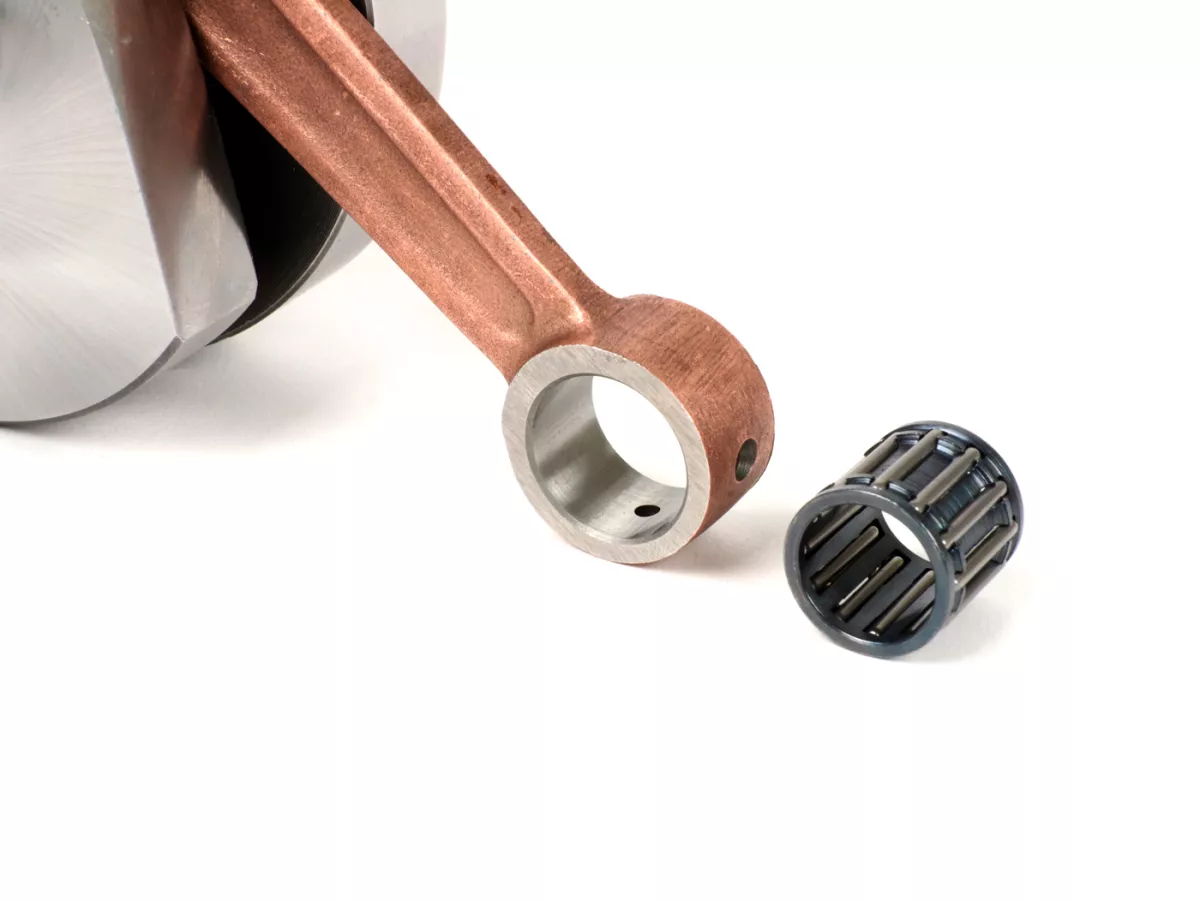

The lower connecting rod bearing is lubricated via two large lubrication slots and a total of four additional pockets on the side. The SSC racing bearing and the side thrust washers ensure a solid bearing. The upper connecting rod bearing is lubricated via two lubrication holes. The INA piston pin bearing is included with the crankshaft.

PLEUEL

The connecting rod is made of extra solid material and, like the crank webs, is drop-forged. The result is an extremely resilient connecting rod that can easily withstand the high torques of today's engine concepts.

HUB

The shaft is available with 60mm (long stroke) and 57mm (standard) stroke. With the long-stroke version, more displacement is achieved, while at the same time the control angles of the cylinder (overflow and exhaust ports) can be changed to increase performance.

INLET ANGLE

Compared to many other racing shafts, the bgm PRO Touring shaft has a significantly better intake timing layout. The standard shaft with its very short intake time cannot keep up with tuning cylinders. The bgm PRO shaft, on the other hand, closes on a PX engine case approx. 65° after top dead center (depending on the engine case, this varies ex works). The engine can be tuned well with these timing angles. TIP: If the intake is machined so that the crankshaft clears the intake slot earlier, additional power can be gained. A good value here is approx. 110-115° from TDC.

RELEASE

The crankshaft design of the PX engines is based on that of the first 125 cc engines from 1960 with an output of approx. 5 hp. Unfortunately, Piaggio never really changed this design in the later increases in displacement. As a result, the crankshaft's load capacity has already been exhausted mathematically, with the standard 200cc models with 12 hp. The crank webs are very narrow and have very little overlap (web material which, viewed in diameter, is available above the lower crankpin). As a result, neither a particularly high pressure dimension nor a large crankpin can be used, as would be necessary (for the performance of today's engines).

For this reason, the BGM PRO Touring crankshaft has a very high material quality and bearings. In addition to the very rigid material, which allows us to guarantee a very strong compression of the crankpin, it is also bonded with a special industrial adhesive for maximum torsional rigidity. Based on the positive experience gained from many thousands of test kilometers of our own engines in daily use, we approve the BGM PRO Touring crankshafts for engine outputs up to 25 hp without restriction. For engines in this power range, we recommend the use of a lightened pole wheel with a maximum weight of 2300gr.

CONCLUSION

The bottom line is that the bgm PRO crankshaft offers the highest quality in all respects with every component. Precision in manufacturing, the materials used and, above all, the precise balancing leave nothing to be desired. This guarantees extremely smooth and vibration-free engine running.

TIP

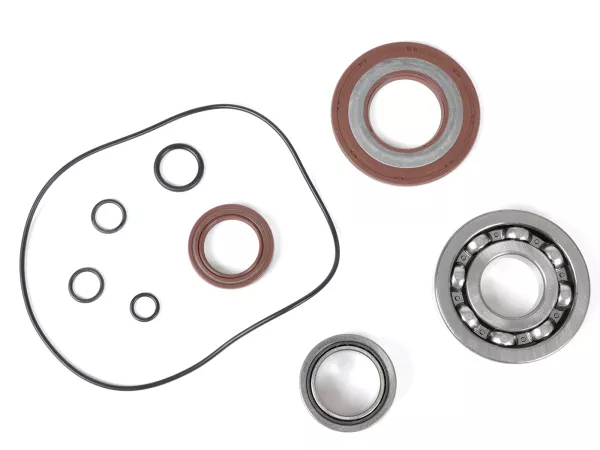

It is best to order the shaft seal 24x35x7 from the Gilera Runner at the same time. The wedge seat of the bgm shaft is wider than usual and can therefore be used with a double-lip FKM Wedi.

AI-translation

DE | €

DE | €