New exhaust for Malossi 210 MHR

In order to bring the potential of the Malossi MHR cylinder for the Vespa PX 200 to the road, an exhaust system has been developed in collaboration with the exhaust manufacturer

Ludwig & Scherer, which gives the cylinder a

powerful and controllable power delivery. As usual with Ludwig & Scherer, the exhaust has a sonorous name: Lara

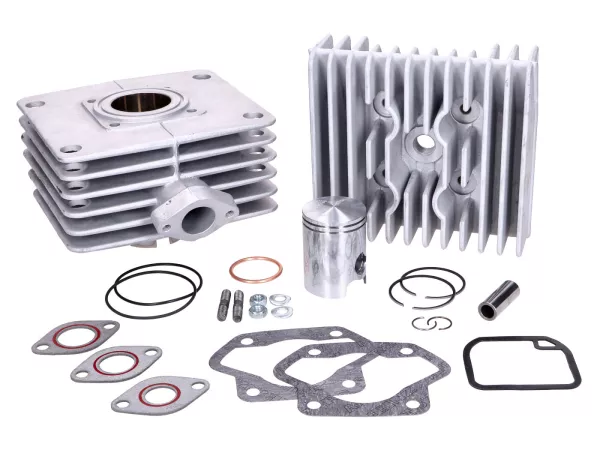

MHR 61mm stroke, Keihin 35 AIRSTRIKER carburetor, V-FORCE, plugged CYLINDER

For engines with high peak power, a usable rev range and early power on the rev side, you have to find the best compromise for the power curve. The curve before the actual start of resonance plays a major role in the resulting driveability. In the diagram above, 15 hp and 20 Nm are already available at 5000 rpm before the power kicks in. The minimum drivability limit for this range is 12 hp at 5000 rpm. Engines that provide less power at identical peak power in this speed range are subjectively rather difficult to ride on the road and have a pronounced "reso kick". The

Malossi 210 MHR cylinder responds very well to exhaust machining. A few more horses can be added to the herd here without much effort.

Same engine as above, exhaust top edge raised by 1mm

But absolute top performance is not the only thing the MHR is good at. Depending on the choice of exhaust system, other characteristics can also be achieved. Here on an engine with rotary valve control and 60mm stroke. The cylinder is only plugged in.

Rotary valve 60mm stroke, Keihin 35mm Airstriker, plugged cylinder

The fairly high power output before the start of resonance at approx. 6000 rpm comes at the price of less peak power. On the plus side, the Malossi MHR cylinder has a relatively short installation length, which results in piston protrusion on crankshafts with 60mm stroke. Depending on the desired engine characteristics, a spacer is therefore required for the cylinder head. Thanks to the centering sleeves of the MHR and the Sport, the use of

spacers on the cylinder head is very simple. The two relevant holes for the centering sleeves can simply be enlarged to a diameter of 9.4 mm. This centers the spacer to the cylinder bore and the protruding piston does not come into contact with the cylinder head gasket.

A 1mm spacer at the cylinder base and a 0.5mm spacer at the (MHR) cylinder head have proven to be quite useful for a 60mm stroke. If the cylinder is only to be shimmed at the base and the exhaust machined to achieve high peak power, the MHR is also able to convert very high control angles into driveable power thanks to the revised overflow system. Values of around 136° overflow angle are not uncommon and work very well, depending on the perephric.

CONCLUSION

If you are looking for high peak performance, the

Malossi 210 MHR With the right choice of components, very impressive performance values can be achieved without much reworking. The Malossi cylinder head is a good choice for almost all configurations and, due to the convergent design, should be fitted with a 1-1.1mm squish at 57mm stroke and approx. 1.2-1.3mm at 60mm stroke *The exhaust from Ludwig and Scherer is expected to be available in a lefthand version from February/March - we will keep you up to date.

DE | €

DE | €