Postage free from 99€ (DE)

High customer satisfaction

- Blog

- No more jumping gears and clattering gears: why the right gearshift is crucial on the Vespa PX

Anyone who has overhauled a Vespa PX engine may be familiar with the frustrating scenario: the engine has been freshly sealed, the gear cross has been replaced, the gears have been checked - and yet the gears still jump out under load. The cause is often not inside the engine, but in an underestimated component: the gearshift detent.

The Vespa PX underwent important gearbox upgrades in the early years of construction. An understanding of this development is crucial in order to select the right gearshift.

Show all details on the transmission history and chassis numbersPiaggio established a new, more stable gearbox type with a different tooth module with the Rally180 (1968). This was used in the P200E models (200cc versions with 23/65 primary, instead of 22/67 on the Rally180).

Early models (still with contact ignition) used the old transmission versions (like Sprint, GTR). This type uses a smaller tooth module and is less stable than the later PX type.

From around 1981, 125cc (from FGSt.-No. 146314) and 150cc (from FGSt.-No. 264565) were also converted to the new gearbox type (21/68 primary). The 150cc used the 35-tooth gear of the 200cc, the 125cc the shorter 36-tooth gear.

The PX80 for the German market received a completely separate, shorter gearbox (albeit with the weaker Sprint gear module), which can however be used with a long primary (25/62) for 177cc tuning.

If gears jump out under load even after an overhaul or if there is a clattering noise when shifting, this is often an indicator of a mismatched component mix or an inaccurate shifting cog.

With the rear wheel free to move (jacked up), check the symmetry of the neutral point:

Ideal production: The gearshift gate is exactly centered in neutral.

Result: If the noise disappears when you turn it slightly, the gearshift gate is not perfectly centered.

A splined gearbox only works properly if the detent points of the shift peg are exactly in line with the position of the gears on the main shaft. With the engine open, you can check the centering of the shift cross visually (e.g. by means of an edge test on the main shaft).

Consequences of shifting: Too little play to 1st gear (rattling when idling) or insufficient depth of engagement when shifting to 2nd gear (gear jumps out under load).

For smaller tolerances, precise spacing of the gearshift detent often helps.

To the spacer kit "The sealant"The geometry of the shift peg changed when switching from PX Alt to PX Lusso (from approx. 1984). This is the most common problem with spare parts.

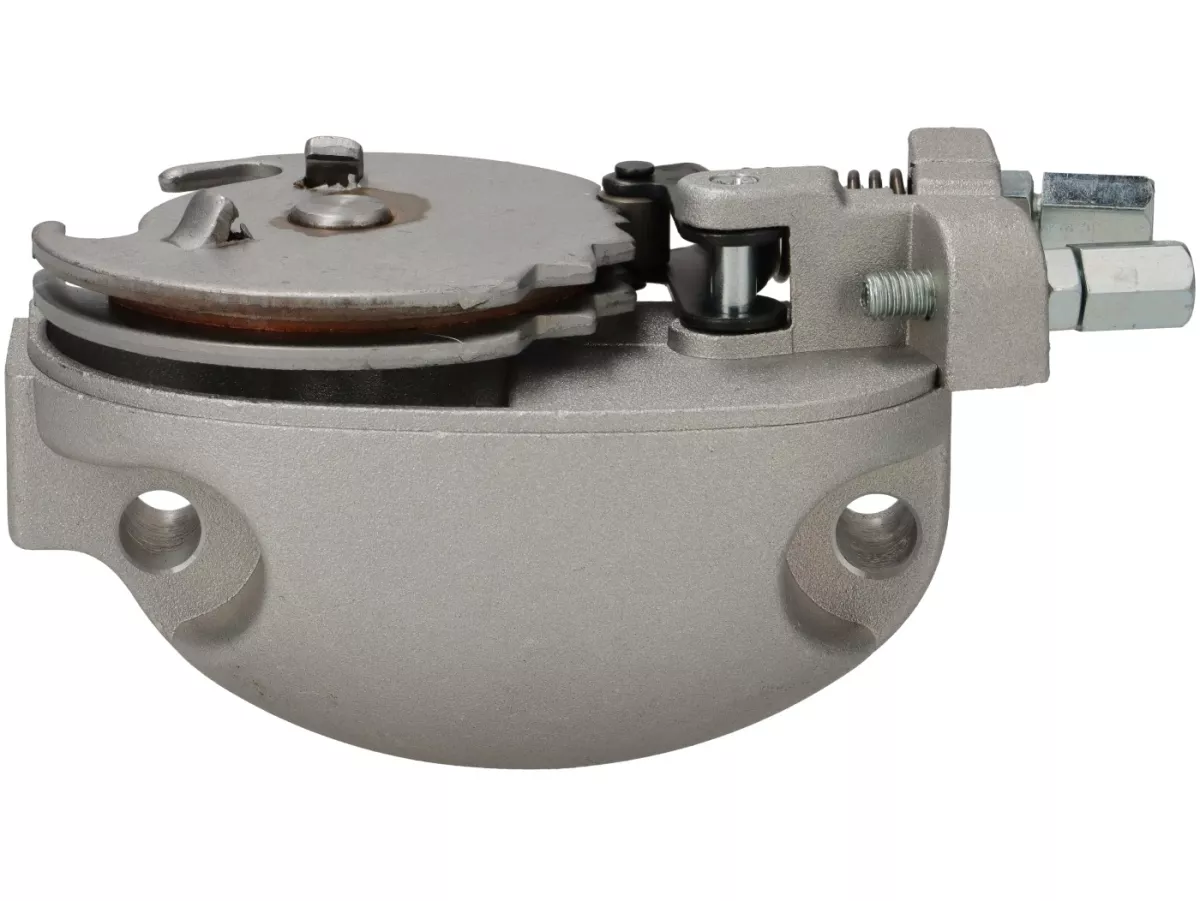

The thrust block is flush (0 mm) with the sealing surface in 3rd gear.

The thrust block must protrude exactly 1.5 mm in 3rd gear.

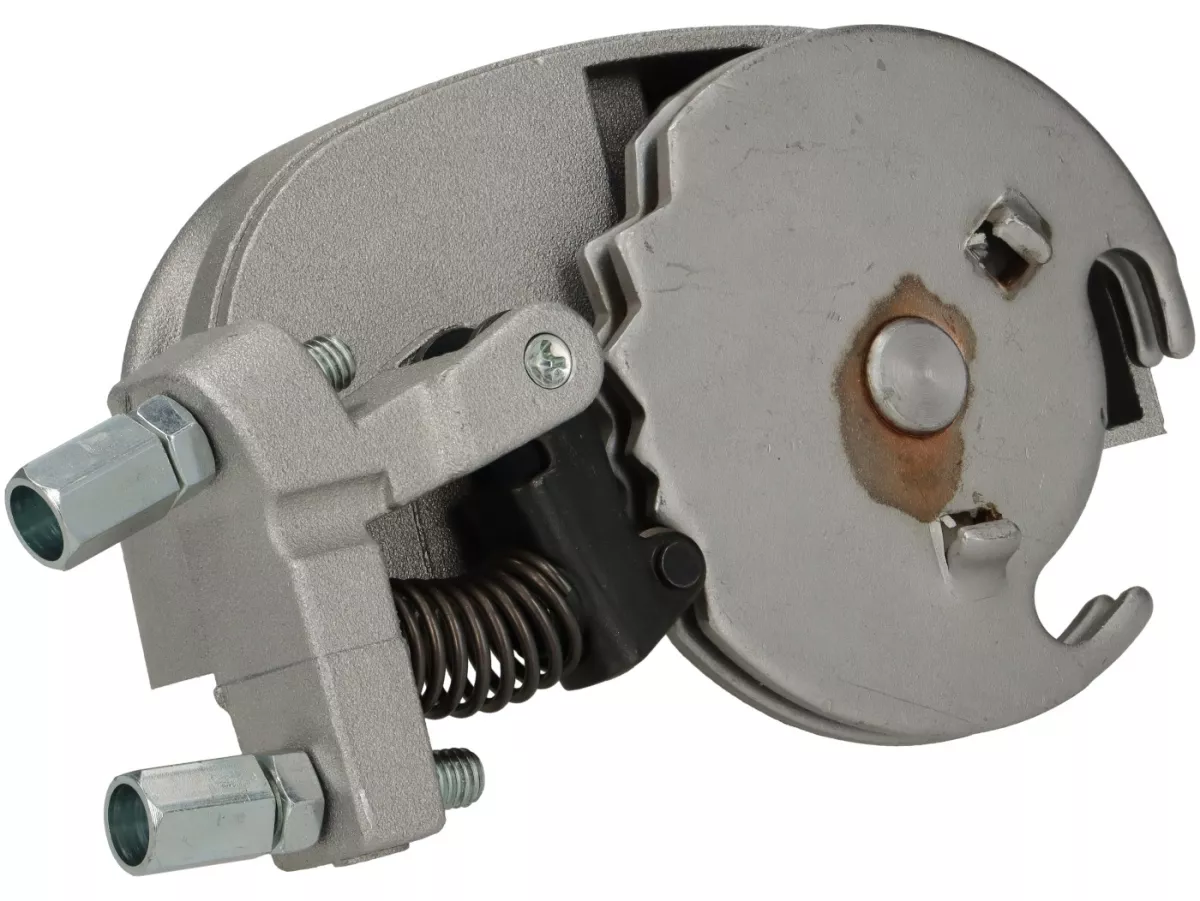

In order to permanently solve this problem, the BGM ORIGINAL shift peg (4-speed) was specially manufactured to meet the requirements of PX Alt gearboxes (1977-1983).

The year of manufacture is not always reliable. Check the width across flats (SW) of the nut on the shift bolt - this is the most reliable indicator:

| Feature | PX Old (suitable for BGM Original) | PX Lusso |

|---|---|---|

| Width across flats (SW) of shift bolt | 13 mm | 17 mm |

| Position of shift pad (3rd gear) | +1.5 mm above sealing surface | Flush (0 mm) |

| Years of manufacture (approx.) | 1977 - 1983 | from 1984 |

A jumping gearshift is not only annoying, it also wears out the entire gearbox. Investing in a component that complies exactly with the specific 1.5 mm protrusion of the "old" series saves time, money and nerves in the long term.