Adapter plate set for conversion PX80/125/150cc engine to PX200 cylinder 12hp.

Which rider of a Vespa with only 80cc or 125cc has not dreamed of experiencing the torque and sovereignty of a 200cc engine in his vehicle?

Powerfully and casually enjoying a mountain pass road without having to constantly use the lower gears?

More power and still have the full reliability of a 200cc engine?

All this is now possible based on an existing 80-150cc engine.

With the adapter offered here as well as a special crankshaft, a slightly modified PX200 cylinder can also be mounted on the small engine cases.

Our adapter set even uses a long stroke crankshaft with 3mm more stroke (60mm instead of 57mm).

This gives the converted engine 208cc and even more torque/power than a stock PX200.

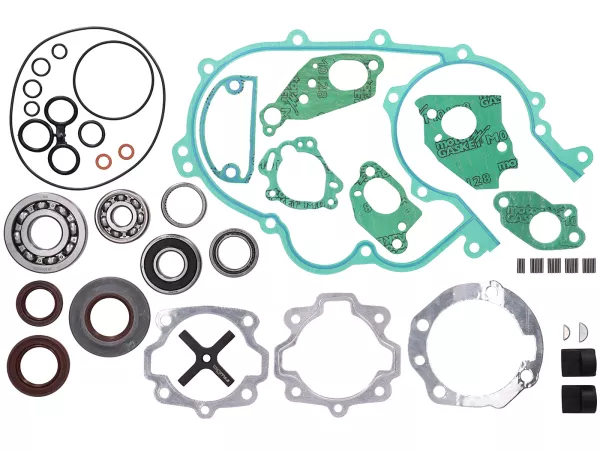

The adapter set includes:

After an idea from Geoff (J&G 2% Vespa Tuning) as well as the technical implementation by W.T. we have the set extensively and long subjected to a full stress test on the road, highway and dyno. The result is so convincing and reliable that we can now offer it as a set for the experienced screwdriver. As a basis a PX80, PX125/150 or also LML 125/150 engine is used. It is also suitable for all engines that already have three overcurrent channels and the PX-type crankshaft (recognizable by a pole wheel nut with M12 thread).

In order to convert this engine to 200cc you will need the following items in addition to the adapter set:

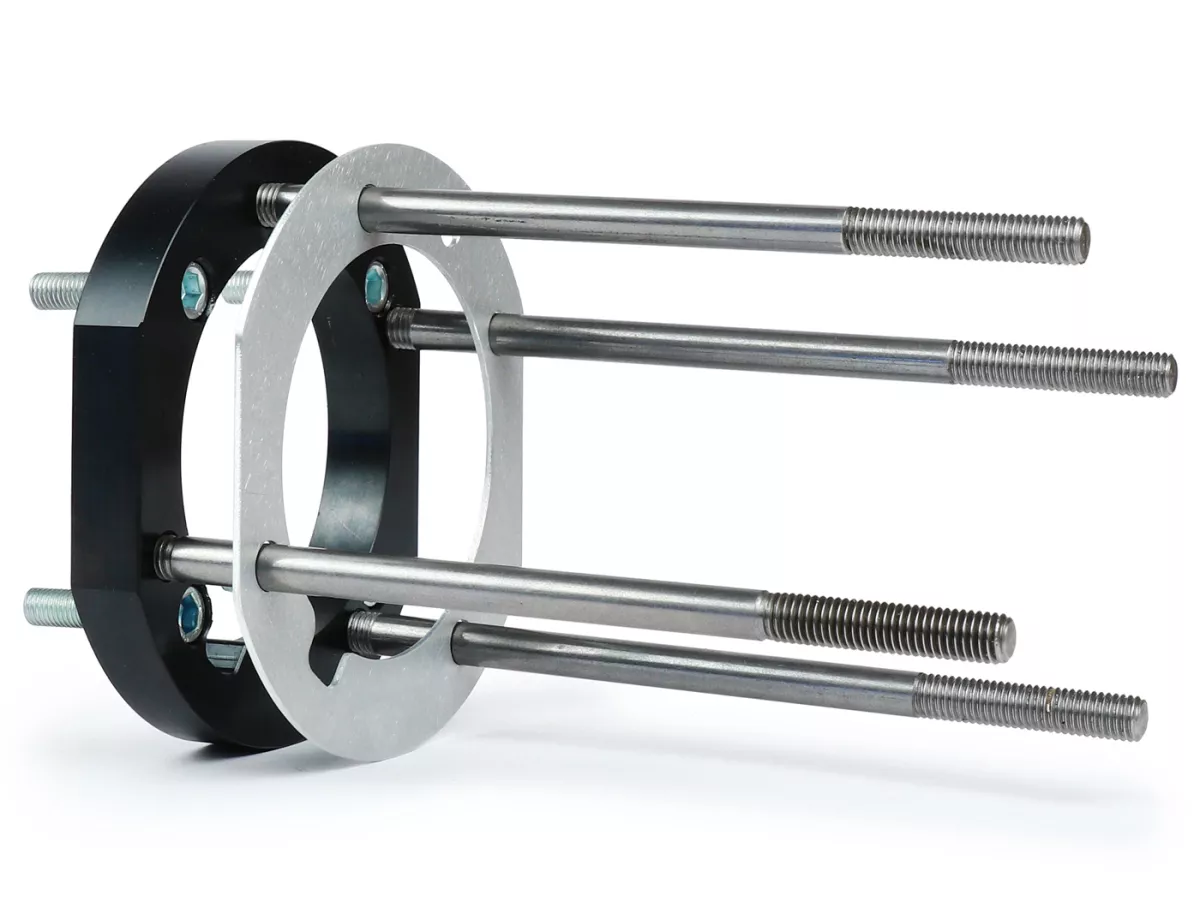

ADAPTER-SET

The conversion is based on a crankshaft with 20mm longer connecting rods (125mm instead of 105mm).

The solid CNC machined steel adapter plate bolts onto the engine case and accepts the studs for the PX200 cylinder. A 1.5mm thick aluminum gasket between the adapter plate and the cylinder base seals the bolt holes and establishes the correct height.

ORIGINAL CYLINDER (no case spindling necessary)

The adapter set SC80200KT (without crankshaft) or SC80200SET (incl. crankshaft) is designed for use with an original (or close to original, e.g. BGM200 (9020017)) PX200 cylinder. Here, the existing cylinder is only shortened slightly at the base (use the adapter plate as a template). This can even be done with a simple hacksaw or flex. The nicer solution is of course the turning on a lathe. It is important to make a chamfer at the end of the cylinder bore so that the piston rings can be easily inserted into the cylinder. But we will also offer directly fitting cylinders. These are based on the BGM200 cylinder, which already has a little more power/torque than the standard cylinder. If you have the possibilities, you can also enlarge the engine housing in the area of the cylinder base (spindle up). Then, in the future, any cylinder that also fits on the original PX200 engines can be used (except for cylinders that already require a longer connecting rod (e.g. Quattrini)).

CURB SHAFT

The BGM crankshaft fits the engine case of the PX80-150cc models without modifications.

It has adjusted timing angles and harmonizes perfectly with the intake of the PX80-150cc models.

CARBURETTOR

The standard carburetor (SI20/20D) can be kept as long as it is adapted by the jetting (use basic tuning of the PX200). However, more power and torque is provided by the carburetor of the PX200 models (SI24/24E). This also has directly the appropriate jetting. For the installation of the SI24 carburetor, the carburetor bowl should be adjusted in the passage (this is done quickly with a file or a Dremel/Proxxon tool).

TRANSMISSION

To make good use of the significantly higher and early torque, the reduction ratio should be extended:

80cc

The PX80 has its own secondary gearbox which is very short (originally the third gear of the PX200 is already longer than the fourth gear of the PX80). If the PX80 gearbox is to be retained, it can be used with an extra long reduction primary from e.g. BGM (25/62). This is used in conjunction with a stable COSA2 type clutch, e.g. a BGM Superstrong clutch. Alternatively, with minor modification work, a gearbox of the PX125/150 models can be used in the PX80 engine cases.

To do this, either the diameter of the auxiliary shaft axle on the alternator side is turned down or the engine housing is enlarged at the mounting for the auxiliary shaft (remove existing bushing).

125/150cc

For the 125/150cc engines, it is sufficient to change to the components of the 200cc engines on the primary side (primary wheel 64Z (BGM) or 65Z, clutch pinion 23Z or 24Z (BGM).

CLUTCH

The 80-150cc models still use small clutches with 6-springs (108mm basket diameter) until 1998. These are permanently not up to the high torque of the 200cc engines. Therefore, this should be changed against a corresponding clutch of the 200cc models. A good possibility to change directly to the most modern clutch type of the COSA2 models. Here there is with the BGM Pro Superstrong a very high quality and stable clutch which is also easy to use.

IGNITION/POLE WHEEL

These can be taken over from the donor engine without any problems. The ignition setting is according to the cylinder (18°-23° v.o.t.). Of course, other ignitions/pole wheels can be used for further tuning purposes. Our test engine ran with the pole wheel BGM Touring with 2300 grams which harmonizes very nicely with the performance characteristics of the 200cc engines.

CYLINDER HOOD

Due to the 15mm increase in the height of the cylinder, the cooling hood must also be extended accordingly. We simply used two hoods and cut off the lower third of one of them. This we then connected with conventional sheet metal screws with the complete other hood. Of course, this can also be solved more nicely, but for us, this method has proven itself in everyday use. Alternatively, the hoods can be welded together with a soldering iron. There are also special plastic welding rods for this purpose, but as a rule you can also use the remains of the sacrificed hood as filler material.

EXHAUST

Because of the higher cylinder it can happen that the exhaust has to be adjusted. Our experience has shown that the Polini box systems must be modified (twist the retaining tabs). The BGM Touring V2 systems (BGM1011TR2) however worked on our setup without any adjustments.

CYLINDER DISASSEMBLY

Due to the raised cylinder, it is not possible to disassemble the cylinder head/cylinder while the engine is installed in the chassis. Alternatively, the stud bolts can be countered with our BGM72M7 tool and unscrewed from the adapter plate when the cylinder is mounted. This allows the head as well as the cylinder to be removed with the engine hanging in the frame. Normally this is a procedure that is not recommended as the threads in the soft aluminum of the engine case are not designed for frequent de/assembly. The original Piaggio studs have a thickened thread on the side where they are screwed into the engine case, which causes them to jam in the case.

However, due to the other studs we use and the steel adapter plate material, this is completely uncritical.

CONCLUSION

If you enjoy engine work and are not afraid of small adjustments, you can build a powerful and durable engine with little effort without having to use a new engine case.

AI-translation

DE | €

DE | €