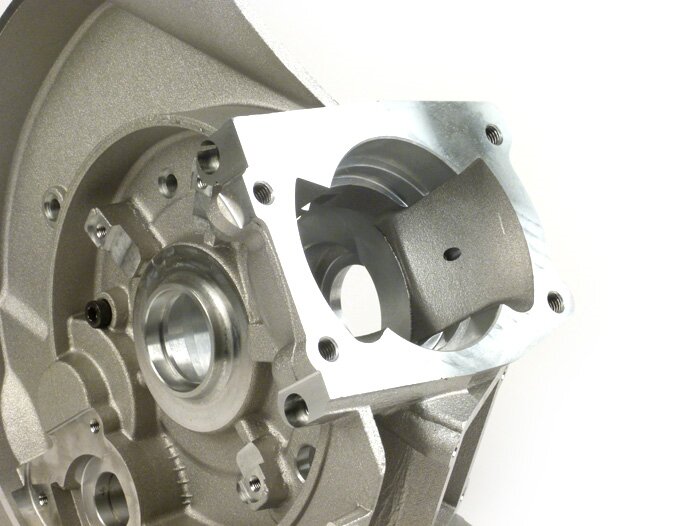

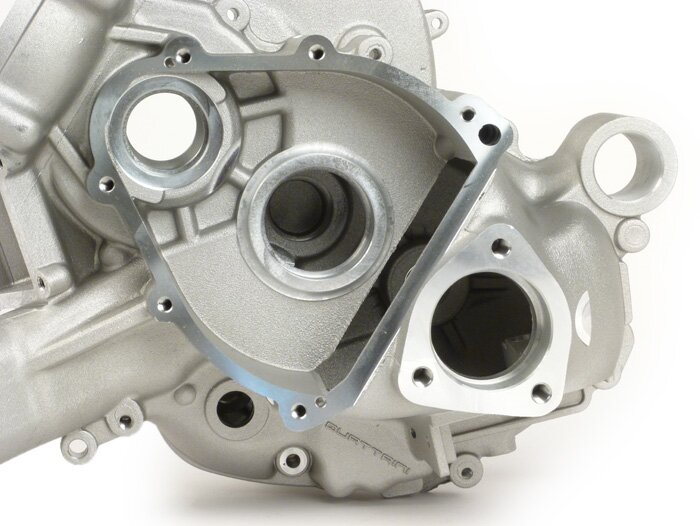

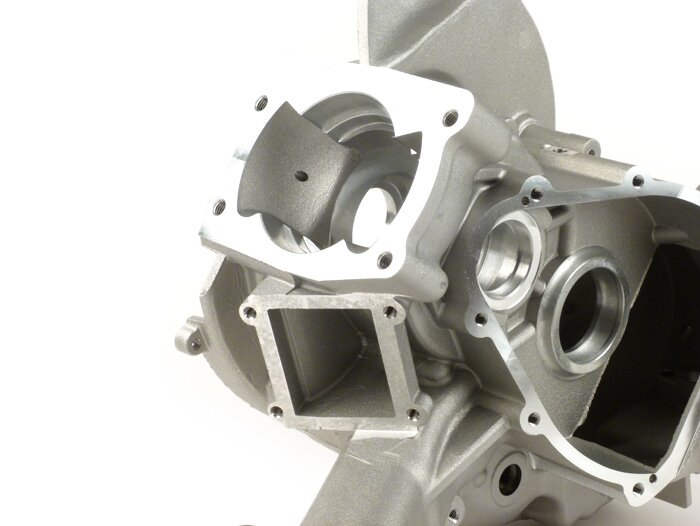

Quattrini engine housing for 200 cc conversions on Vespa Smallframe

Satte 200ccm offers Max Quattrini for the classic Vespa models such as V50, 50N, SS90, PV125, ET3, PK S, PK XL etc.. With the individually available parts, a fuselage engine kit can be put together, consisting of:

This not only goes beyond the scope of the usual displacement classes that have been installed in these vehicles up to now, but despite the enormous increase in displacement and power, it is extremely solid in terms of both design and craftsmanship

. The basis is a completely redesigned engine housing, which is cast from a high-strength alloy. This now finally offers space for a significantly wider and therefore extremely stable crankshaft with a whopping 56.5 mm stroke (series PV125 is 51 mm stroke). In conjunction with a 116 mm connecting rod, this creates a very solid basis for the powerful 200cc cylinder from Quattrini. This was deliberately designed so that it develops enormous thrust even at low engine speeds and still develops over 30 hp and 30 NM out of the box! This means that the wide-ratio standard gearbox can continue to be used without any problems. Gear connection problems are ruled out due to the very wide and substantial power band.

ZYLINDER:

- Displacement: 200cc

- Bore: Ø67mm

- Stroke: 56.5 mm

- Exhaust stud spacing: 66 mm (M8)

- Piston Wössner 41613-1 (Ø66.93 mm)

- Running clearance 0.07 mm

- Piston rings Wössner RSB6700

- Clip CW16 (C-type, 16x1)

- Spark plug long thread

- Cylinder base bolts: M8x55 hexagon socket

- Cylinder head bolts: M6x30 hexagon socket

- Intake manifold screws: M6x25 hexagon socket

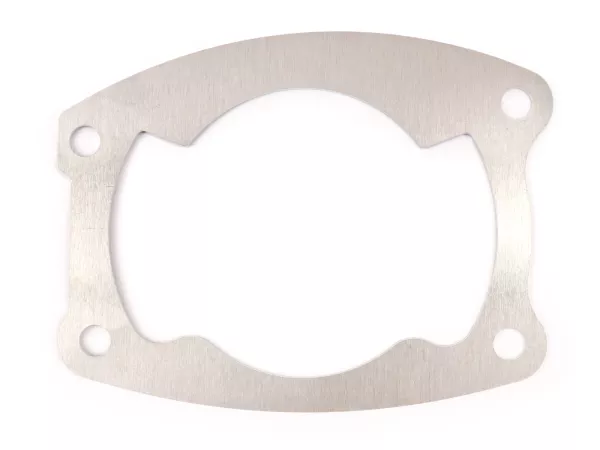

- Cylinder base gasket: 1x 0.35 mm

- Cylinder head gasket: no

- Duct height main outlet 35.3 mm

- Duct height OD 47 mm

- Cylinder head immersion: 1 mm

CRANKSHAFT:

- Quattrini extra wide, connecting rod 116 mm

- Stroke: 56.5 mm

- Connecting rod bearing 16x20x19

- Crank webs: Ø89.5 mm

- Bearing seat: 25 mm stub

- Shaft seal seat: 20 mm

- Cone: PK XL

- Thread Lima M12x1.25

- Thread drive M12x1.5

ENGINE CASING:

- Crankshaft oil seals: 24x35x7mm FKM

- Crankshaft bearings: 2x 6205 TN9 C3

INTAKE MANIFOLDS:

- Intake Ø42mm outside, Ø35mm inside

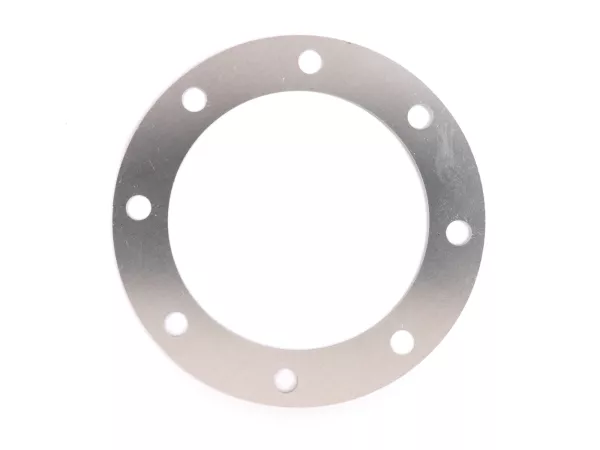

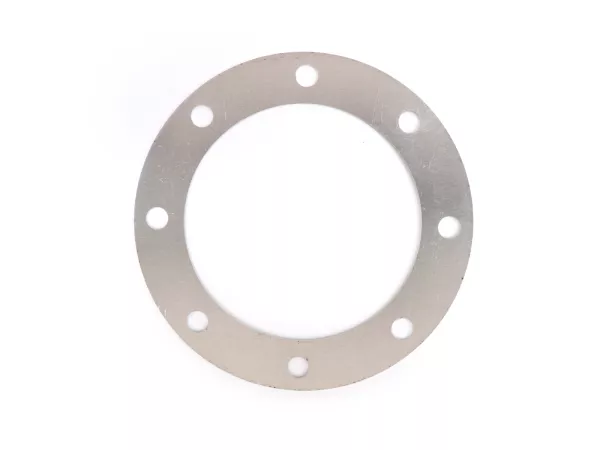

- Diaphragm, 4 flaps, material thickness 0.5 mm

The cylinder has a diaphragm inlet, so the diaphragm inlet already provided in the engine housing but still potted is not required. The crankcase of the 200cc engine housing now uses larger bearings of category 6205. As the crankshaft seal on the drive side is now located outside the crankcase, the shaft is no longer secured against shifting by screwing the primary pinion. It is therefore necessary to use a guided bearing on at least one side. We offer two high-quality solutions for this:

- 6205 TN9 C3 locating bearing with polyamide cage

- 6205 MA C3 locating bearing with brass cage

Special features:

- No standard ignition can be used

- Can be used with original gearbox

- Cylinder cooling cover must be modified

- Can be installed in all Smallframe frames (except automatic models)

We recommend a Keihin PWK33 or PWK35 carburetor to match the intake manifold. Alternatively, Max Quattrini recommends a Dell'Orto VHST26 carburetor (jetting: HP: 135-138, LP: 35-38, mixing tube: HE270, needle: D36, slide 50)

In order to enjoy the powerful torque in the long term, a Hartz4 clutch and clutch cover from the PK XL2 models should be used. The long primary reduction ratio of the 125cc models can be used without any problems (27/69 = 2.56). Spark plug NGK B9EG. Tires: 3.50-10. Vespatronic setting 25° at 1500 rpm.

The engine housing does not use sealing paper. It is sealed with a liquid sealant such as Loctite 510 or Normfest Plastomar. Tightening torque of the cylinder screws 18-20Nm (M8). Tightening torque of housing screws 8-10Nm (M6). Quantity of gear oil: 500ml mineral monograde oil (e.g. Runge SAE30). Oil mixing ratio: 4% (1:25)

We expressly point out that although the kit as such is matched to each other, assembly requires a skilled hand and further adjustment work, depending on the other components used and the respective base vehicle.

Points that should be taken into account during assembly:

- Adjusting the cylinder cover

- Distance between wheel/tyre combination and exhaust

- Distance between shock absorber and fixing screw of shift fork

- Distance between shock absorber and exhaust manifold

- Distance from side bonnet closer to bonnet

(US)

DE | €

DE | €